Juice Processing & Bottling Machinery

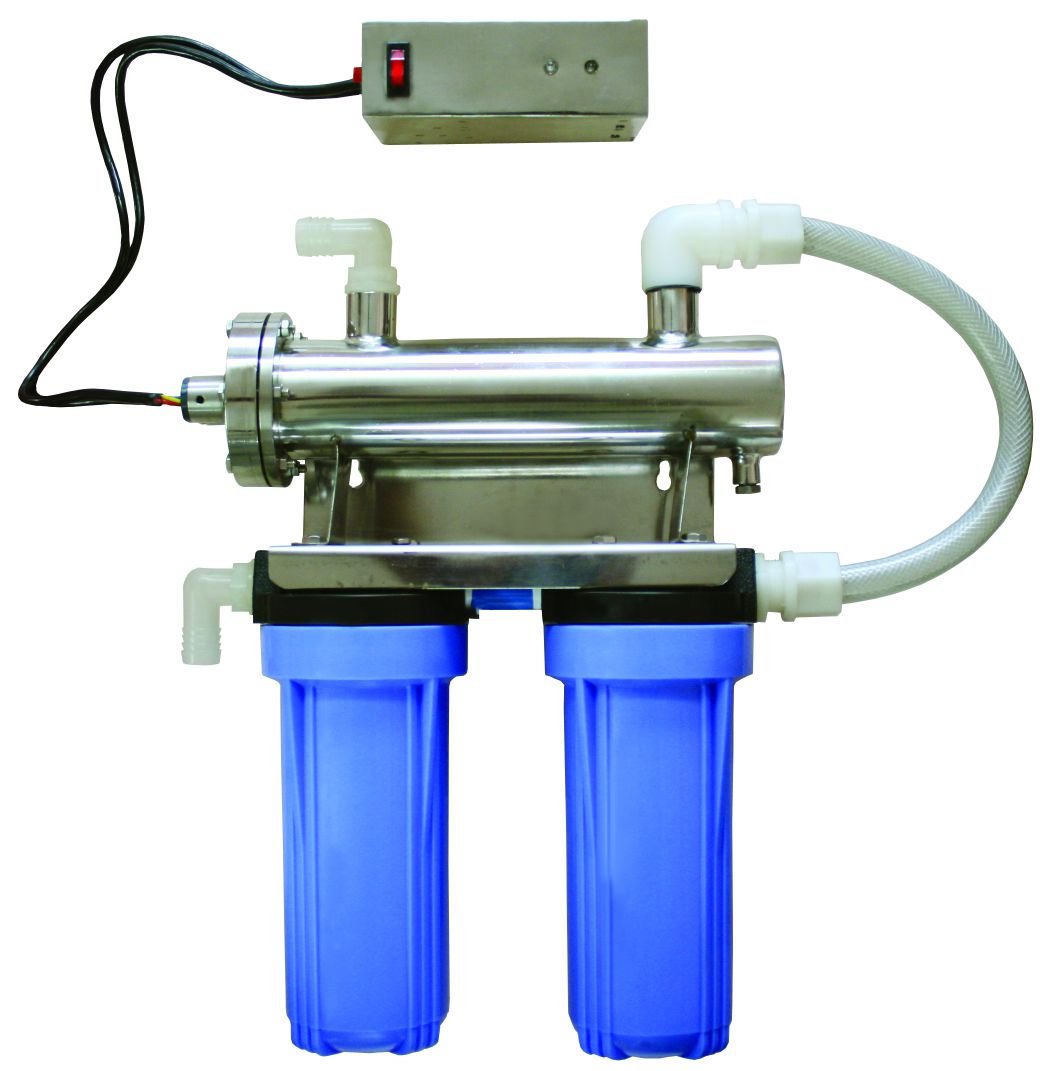

Ultra Violet Water Filter

Ultra Violet Water Filter System is ideal for filtration of Bore well and Well water. It is a 3-in-1 filter system.

It has a 10 micron filter cartridge which removes all visible dust particles. The water then flows through an activated Carbon Cartridge which removes chemicals and odour. Then the water flows through the UV chamber where two UV lamps are provided. They help to eliminate bacteria , germs, pathogens etc.

The filter can process about 500 litres of water per hour. It can be connected to an overhead tank and the water will flow through it by gravity. There is no need for pumps.

It is wall mountable and easy to assemble. It requires very little maintenance and is user serviceable.

It is an ideal unit for Soda / Soft drink makers, juice processing factories, hostels, hotels, etc. and wherever bulk drinking water is required.

Sand Water Filter

The Sand Water Filter is used for filtering out all visible dust particles from water. To a certain extent, It also removes chemicals and odour from water.

The filter is made of Fibre Reinforced Plastic (FRP) and is therefore maintenance free. The FRP material is ideally suited for water filtration tanks and is very strong and rigid. The tank requires no painting and does not rust.

Water passes through three layers of special Quartz stones and sand and a layer of Activated Carbon. A 10 micron filter cartridge is also provided at its outlet to remove tiny dust particles.

A system of pipes and ball valves is provided which are attached to the main portion of the tank. The filter can be connected to an overhead tank and the water flows through the filter by gravity. About 500 litters of water can be filtered per hour.

Other than periodic backwash and a change of carbon, the filter requires very little maintenance.

It is an ideal unit for Soda /soft drink makers, juice processing factories, Hostels, Hotels etc and wherever bulk drinking water is required.

Reverse Osmosis Filter Unit

Reverse Osmosis is a technology that is used to remove a large majority of contaminants from water by pushing the water under pressure through a semipermeable membrane. The unit consists of a comprehensive set of filters like –

- Prefilter to remove dust

- Carbon filter to remove chemicals and other off smells

- Ultra violet lamps to kill harmful bacteria and viruses

- Reverse Osmosis filter unit to remove contaminants

- Ozonator (Optional)

- Other filters can be added depending on the inlet water quality.

The unit is easy to install and requires minimum maintenance. It is made for reliable performance.

The whole unit is mounted on a skid so it is easy to transport and can be quickly installed. Each filter unit is connected to the next in line with necessary pipes and fittings. Pumps are also provided.

The different filter stages are selected depending on the quantity of water available and so a Water Test Report is essential. Based on the report, the system can be tailored to get best results.

The unit is easy to install and requires minimum maintenance. It is made for reliable performance.

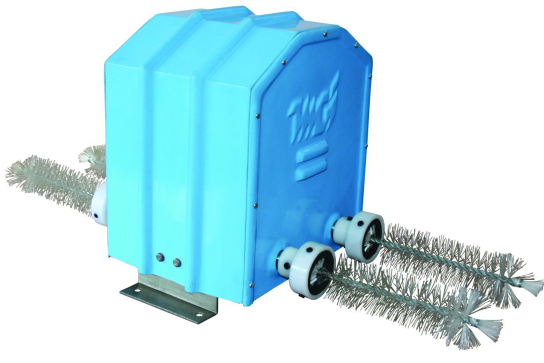

Brushing Unit with FRP / SS Cover – for Glass Bottles

- The Brushing unit is used for cleaning glass bottles.

- It is assembled on a stainless steel base plate with a Fiber Reinforced Plastic (FRP) SS cover.

- This cover protects a 1/2 HP I Phase 230 V 50 Hz motor. The motor is connected to two stainless steel shafts with pullies and V-belt.

- This unit must be mounted on the center of a cement / stainless steel/plastic tank of height 2.5 –3 feet. The size of the tank depends on the space availability and the number of bottles to be washed. The brushing unit thus mounted has two brushes extending on one side and two brushes on the other. Therefore two people standing on opposite sides of the tank can at once clean 4 bottles.

- Once the bottles are brought back from the market, they are soaked in another tank containing water with soap solution. This ensures that all dirt particles are loosened. The bottles are now ready to be brushed.

- There are two types of brushes mounted on the unit. One long brush cleans the inside of the bottles and at the same time another brush cleans the mouth of the bottle where there is generally rust formation due to crown corks. Two persons can wash approximately 8-12 bottles per minute. This depends on the dexterity of the workers and dirtiness of the bottles.

- After the brushing the bottles can be rinsed with plain water with the help of Rinser.

- The Maintenance of the machine consists of greasing, V belt tightening whenever required and general cleaning

Rinser with 12 Cups – for PET Bottles

This unit is meant for rinsing 12 PET bottles at a time. It can be fitted on top of a cement/plastic or SS Tank. It has 12 nozzles fitted on SS pipes and connected to a central pipe with ball valve which is connected to a water source like overhead tank or pump. All contact parts are SS 304.

12 Bottles are kept upside down in the nylon cups. When the ball valve is opened, water jets into the bottles and rinses them. The rinse water falls back into the tank below and can be drained or recycled as required. About 24 bottles can be washed in a minute depending on the speed of the operators. The unit requires very little maintenance.

The Rinser can wash any size of PET bottle from 200 ml to 2000 ml. It can also be altered to suit bottles of different mouth diameters, shapes and sizes

Rinser with 12 / 24 Cups with Pump & Tray – for PET / Glass Bottles

- The Motorized Rinser is ideal for high-speed jet rinsing of PET / Glass bottles.

- The pump must be used in case overhead tank is not available.

- The Rinser is mounted on a portable SS table with a water collection tray.

- A monoblock pump is provided to jet the water into the bottles.

- Water connection is made to the inlet of the pump.

- The outlet of the pump is connected to the three way ball valve of the Rinser.

- The bottles are kept upside down in the rubber cups.

- Ball valve is opened and the bottles are rinsed.

- The rinsing water falls back into the collection tray and can be reused after filtration or drained.

- Once the rinsing is over, the three way ball valve can be closed to load the next lot.

- Mean while the pump is on and the pumped water is recycled back through the third port of the ball valve.

- About 24 / 48 bottles can be washed per minute depending on the speed of the operator.

Wood Fired Boiler

Wood Fired Boilers are used for the generation of steam for heating for various industrial applications. Boilers are available in different sizes and with different output capacities.

It uses firewood as fuel. The Boiler is mounted on a sturdy stand and its internal construction is designed for maximum efficiency.

The Boiler’s main body is double jacketed and is made from optimum thickness MS plates.

It has an SS tank which is filled with water which is heated to make steam.It is fitted with the necessary pressure release safety valve, pressure Gage to monitor pressure, Gage glass tube to check water level in the tank and all safety features.

The Boiler is mounted on a rigid MS Grate below which the ash is collected after burning. A 10 ft long pipe is provided for the exhaust smoke. The Boiler can be mounted in an open area with a covered roof. The Boiler can be selected as per the quantity of steam required

Double Jacketed Steam Kettle with / without Stirrer

The Double Jacketed Kettle is ideal in Food Processing industries for heating fruit juices & pulps, ayurvedic medicines and preparation of sugar syrup. It can be connected to a steam boiler with suitably insulated pipes. The steam is circulated within the outer jacket thus heating the contents.

The design of the steam kettle makes heating and cooking very efficient and fast. It can be used by all industries wherever liquids need to be heated. The Kettles are available in varying configurations as follows:

Capacity can vary from 50 liters to 500 liters.

They can be supplied with or without a stirrer to heat the contents evenly. When supplied with a stirrer a motor, gear box and a fan are provided on the top. The fan stirs the contents slowly and evenly for uniform heat.

They can be supplied tilting type or non-tilting type. In case of tilting type, we can provide a manually operated gear box or a motorized gear box to help to smoothly tilt it without the operator feeling the load. When it is non tilting type, it can be provided with a bottom drain outlet.

The inner and outer layer of the Kettles are both fabricated in thick SS 304 sheets to bear the pressure of steam. The Kettle can be made to suit specific requirements and purposes. It’s design takes care of all safety features.

Fruit Mill

The Fruit Mill is basically a pulverizer. It has a motor and a funnel on top through which the fruits can be fed into it. The fruits pass through the funnel into a breaking chamber where there is a fan with a blade. This blade hits the fruit and breaks it into pieces. The broken fruits are then ejected out of the machine through a chute.

It’s a simple machine and does not require any maintenance except for a thorough cleaning.

All contact parts of the machine are SS 304 and the stand is made of MS. Suitable for crushing fruits like apples, pineapples etc. before pulping or juice extraction.

Available Models:

- 1 Hp – 500 kgs per hour

- 3 HP – 2000 kgs per hour

- 5 Hp – 2500 kgs per hour

Fruit / Vegetable Pulper

The Pulper is an ideal machine for extracting pulp of Tomatoes, Mangoes, Raspberry, Papaya, Pineapple, Jamoon, Grapes etc., and many other fruits and vegetables. Some of these may require to be heated to make them soft before putting them in the Pulper.

It consists of a stainless steel hopper, drum, chute and steel sieve. It is very simple to operate. The material is manually fed into the hopper. It is drawn into the stainless steel sieve in which a nylon brush is rotating. The brush scrapes the material on the sieve and its pulp is extracted. The pulp flows out of the machine through a chute. The waste material like fibers, seeds etc are ejected at the bottom.

Its maintenance is simple. The stainless steel sieve and brush are easy to dismantle and clean after use. The brush may require to be changed depending upon usage.

The machine is available in various capacities as follows:

| Motor | Processing Capacity / 8 hours |

|---|---|

| ½ Hp I ph | 500 kgs |

| 1 Hp I ph | 1000 kgs |

| 3 Hp III ph | 2000 kgs |

| 5 Hp III ph | 5000 kgs |

Note: The processing capacities mentioned above will vary according to the fruits/vegetables used.

Sugar Syrup Filter Press

The Sugar Syrup Filter Press is used to remove all dust and particles that are found in sugar when it is made a syrup. It is fabricated fully from SS 304. It has a capacity to filter about 500 liters per hour. It has a 1 Hp motor and SS pump. The filter section has 7 special filter pads through which the sugar syrup passes and is completely filtered.

The filter tank is fitted with a pressure gage, safety release and air release valve. The filter pads have to be cleaned each time they are used. However, they have to be changed periodically depending on their usage. The filter tank and its connecting pipes can be dismantled and cleaned in a short time. The filter press assembly is

mounted on wheels for portability.

Bottle Sterilizer – for PET / Glass Bottles

Sterilization refers to any process that eliminates, removes, kills, or deactivates all forms of life and other biological agents present in a specified region – such as a surface or a volume of fluid. The process of sterilization of glass and PET bottles before and after filling basically improves its shelf life and ensures that the product the customer consumes is safe.

The method of sterilization is dipping in hot water for a specified time. The sterilizer is basically an SS tank whose size depends on the number of bottles to be sterilized. Water is filled in the tank and heated to the required temperature by steam from boiler or electrically with heaters. Baskets made of SS sheet with SS mesh bottom are provided. The sizes & quantity of the baskets also depend on the number of bottles to be sterilized. The bottles are loaded into a basket and it is dipped into the hot water. The baskets can be manually handled when the number of bottles are less or for larger quantities a winch can be provided. Meanwhile the next basket is filled with bottles. After the required time, the first basket is taken out and the next one is dipped into the tank. So the sterilization continues.

Glass bottles can be sterilized before and after filling and capping. PET Bottle can be sterilized after filling and capping. The tank and baskets are fabricated out of SS 304 and built to last. The Sterilizer can be supplied to suit the number of bottles to be sterilized

Fruit Juice Machine Centrifugal Type

- The Machine is ideal for extraction of juices from many types of fruits and vegetables

- All the contact parts except the inlet chute are of SS 304

- It is suitable for continuous operation.

- It can be easily disassembled, cleaned and refitted for use within 5 minutes.

- The machine requires very little maintenance.

- It is available with ½ Hp I ph motor suitable to process about 500 kgs of fruits / vegetables in 8 hours & 1 Hp I ph motor suitable to process about 1000 kgs of fruits / vegetables in 8 hours.

- The machine can be installed on a table or a stand. The fruits / vegetables are put in the chute from the top and pressed down with the help of nylon pusher.

- The juice flows out of a small juice outlet pipe on the side of the machine where it can be conveniently collected.

- The scrap falls out of the large pipe on the side of machine.

- The machine can be used for apples, grapes, oranges, mosambi, ripe guava, ripe pineapples, ripe mangoes, Lichees, peaches, apricots, pears, watermelon & vegetables like carrots, beetroots, tomatoes etc.

- Note that large seeds inside fruits / vegetables must be removed before putting in to the machine to avoid damage to the inner plate.

- If the fruits / vegetables are cut in to pieces before putting them in, the machine will work more efficiently and effectively.

Fruit Juicer Machine Cold Press Type

- This machine is ideal for all citrus fruits.

- It is a counter top machine for fruit stalls, juice shops etc.

It is available in two capacities as follows:

- 1/2 Hp I PH motor – capacity is about 60 kgs per hour

- 1 Hp I PH motor – capacity is about 100 kgs per hour

The machine is very easy to use – the whole fruits are peeled and pushed into the hopper one after the other with the help of the wooden/nylon pusher provided. They get squeezed by the turning screw inside the machine and juice starts flowing out. The skin, fibers and seeds ect are ejected out separately.

The machine can be dismantled and cleaned in a very short time.

Lemon / Orange Juice Machine

This is a heavy duty machine suitable for continuous “Cold Press” extraction of juice from unpeeled whole lemons/Oranges. The machine for lemons and Oranges although similar in appearance have different cup diameters. Both machines can process 30 fruits per minute.

The machine is made out of SS 304 and is robust. It has a 1 HP I ph geared motor inside. Unpeeled Lemons/Oranges are placed in the chute above the machine. As they roll into the machine one after the other, the fruits are cut in half by the center blade – one half of the fruit is squeezed by the left hand rotating cups and the right hand by the rotating cups on the right side. Juice passes through a stainless steel mesh and out of the machine through a chute in the middle at the bottom of the machine where it can be collected. The squeezed peels with the flesh and seeds are ejected on both sides of the machine.

The machine can be installed on a table and connected to a 230 V 15 A power socket. It requires very little maintenance other than the complete cleaning of the machine after use. An acrylic sheet is provided in the front so the extraction process is visible and at the same time there is no splashing. This sheet can be taken off for cleaning of the front portion of the machine. The machine can extract almost 90% of the juice content of each fruit – but this depends on its ripeness.

Motorised Liquid Stirrer

- The Stirrer is basically a mixer with a fan blade at the bottom.

- It is used for stirring/mixing liquids like juices syrups, curd etc.

- It is also most useful in the food, rubber, chemical and other industries where a homogeneous mix of the liquid is critical to product quality.

- The Stirrer consists of a high-speed motor mounted on a bell housing from where four stainless steel rods extend down and support a frame of stainless steel plates with holes.

- The motor shaft is connected to the fan blade at the bottom with a central stainless steel shaft.

- The stirrer is hung inside the container holding the liquid with the help of a wire rope and winch provided. The bottom of the stirrer is kept about six inches above the bottom of the container.

- When the motor is switched on, the central shaft turns and rotates the blade.

- The blade pushes the liquid through the holes in the stainless steel frame and thus the liquid is broken up into bits and mixes well.

- The stirrer is used for 10 minutes – 30 minutes as required.

- The size of the stirrer may vary according to the quantity of liquid to be mixed at a time.

- The stirrer has an advantage over the conventional mixers in that the liquid is mixed by breaking it up rather than making it revolve in the container.

- This Stirrer with a ½ Hp I Ph motor can be mix about 100 liters of liquid at a time.

- If the liquid is too viscous or foaming type, the Stirrer can be specially made to suit the liquid quantity &application required.

Colloid Mill

Colloid Mill is an ideal and perfect homogenizer-cum-emulsifier. It is used for thoroughly mixing of two or three different types of liquids. It finds its application in various processes like grinding, homogenizing, emulsifying, dispersing, mixing, extracting etc., catering to the needs of several industries, such as

- Pharmaceutical

- Food

- Dairy

- Sweet meats and

- Confectionary

- Chemical

- Paint

- Textile

- Cosmetic

- Soaps and

- Detergents

- Rubber

OPERATION

In the Colloid Mill the product is subjected to high shearing, cutting, and rubbing forces between two toothed surfaces. The ground material continuously leaves the mill through the outlet pipe, and if required, it can be re circulated.

SALIENT FEATURES

- All contact parts can be easily and quickly dismantled and cleaned

- Machine is designed for continuous operation

- Cylindrical screen for higher output

- Feed Hopper, recirculating pipe and mouth hopper

- are supplied as standard with Colloid Mill

- All contact parts of the mill are made of Stainless Steel 304.

Homogeniser

Homogenization is a process used to emulsify one liquid into another or uniformly disperse solid particles throughout a liquid to improve important product qualities. We manufacture a durable range of homogeniser machines which comprises of positive displacement pump. The displacement pump forces the product under high pressure through a small adjustable gap between the valve and the valve seat, causing turbulence and intense mixing. The advantages of this machine are

- Enhanced Color

- Longer shelf life

- More uniformity

- Viscosity Control

- Improved Stability

- More consumer appeal

- Improved reaction time

- Enhanced texture and taste

- Batch-to-batch consistency

- Particle size control & uniformity

It useful in the following industries

- Juice Processing

- Chemicals

- Dairy

- Paint

- Pharmaceuticals

The machine is sturdily built and all contact parts are SS 304. It is available with the following output capacities.

| Motor HP | Output Capacity |

|---|---|

| 3 HP | 300 liters / hour |

| 5 HP | 500 liters / hour |

| 10 Hp | 1000 liters / hour |

Volumetric Liquid Dosing Machine –Motorised

The Volumetric Liquid Dosing Machine is ideal for filling non-viscous liquids in accurate preset quantities. The quantity per fill can be adjusted. It is meant for liquids without particulate matter.

The machine consists of a motor and gear box and has one or two pumps attached as required. Each pump has two hoses connected to it – one is for liquid suction and the other is for liquid delivery into the filling medium. The suction hose can be connected or dipped into the container holding the liquid to be filled. Liquids can be filled in glass bottles, PET bottles, Tins, Cans or pouches as required.

The number of bottles that can be filled depends on the volume of output per fill, density of the liquid & mouth diameter of the container being filled.

It is an easy machine to use and requires little maintenance limited to the change in washers in the pump and oil for the gear box.

The machine is available with the following options:

| Fill Range | Output / Minute | Motor HP |

|---|---|---|

| 5 ml – 50 ml | 56 BPM | ½ HP |

| 20 ml – 100 ml | 56 BPM | ½ HP |

| 50 ml – 300 ml | 28 BPM | ½ HP |

| 100 ml – 500 ml | 14 BPM | 1 HP |

Note: BPM will vary according to viscosity of liquid, bottle mouth diameter and size. The above output quantities are only indicative.The main advantages of the machine are:

- The machine is sturdily built of SS 304 and all contact parts are also SS 304.

- It can fill hot liquids (up to 80 degrees Celsius) also.

- For this the inlet and outlet hoses provided are Silicon Braided.

- Bottle Tables to hold the bottles while filling can be provided.

- Accurate fill quantities

- Fast filling

- No spillage & wastage

- Liquid fills untouched by hand.

- The pumps can be easily dismantled for cleaning after use.

Gravity Liquid Filling Machine for PET / Gloss Bottles – 4 / 8 Head

The Gravity Liquid Filling Machine is ideal for filling all non-viscous liquids like Juice, Mineral Water, Milk, Ayurvedic medicines, Non corrosive chemicals, liquid soaps, Coconut oil, Edible oils etc in PET or Glass Bottles. It is available with 4 or 8 filling heads. It can fill any size of bottle from 200 ml to 2000 ml. The machine can be altered for filling special shaped bottles also. It consists of a SS tank of capacity 175 liters (for a 4 head machine) and 225 liters (for a 8 head machine.

Mode of Operation:

- Liquid is poured into the tank – manually or by a pump.

- Requires one person for a 4 head machine and 2 persons for a eight head machine.

- Four / eight bottles are held on the bottle holding plate by their necks.

- Foot Lever is pressed.

- The bottles go up into the filling heads with the filling nozzles inside the bottles.

- The liquid starts to flow into the bottles.

- O nce the liquid level reaches the nozzle level, the foot lever can be released and the filled bottles can be taken off.

- The above process can be repeated for the next batch.

Optional Features Available:

- The Machine can be pneumatically operated – for this an air compressor is required.

- The machine can be used for filling hot liquids – the tank in which case can be supplied with insulation to retain temperature while filling.

- T he machine can be supplied with an SS pump to fill the liquid in the tank.

- A liquid level sensor to switch the pump on and off can be fitted to maintain liquid level inside tank.

- A PET Bottle capping machine can be fitted on one side of the machine so that capping can be done immediately.

Advantages:

- It is simple to operate.

- Requires no skill.

- Ladies can operate.

- It does not require power.

- Maintenance is simple and minimal and limited to change of washers & spring in the filling valve. The frequency of change depends on the type of liquid being filled and the number of bottles per day.

- Accuracy of fill quantity is maintained. Liquid will not overflow even if there is a delay in releasing the foot pedal.

- Final fill level inside bottle can be adjusted.

- The valves can be easily dismantled for cleaning and quickly refitted again.

- The tank can be cleaned – a drain valve is provided at its bottom for this.

- A Gage glass level tube is fitted on one side of the tank so the liquid level in it can be monitored.

- Production of about 10-12 bottles/minute can be achieved (250 ml bottles) for a four head machine and 20-24 bottles/minute for an eight head machine. But

this depends on the operator’s speed and dexterity.

Semi Automatic Timed Gravity Liquid Filling – Linear – with PLC Machine

The Semi Automatic Liquid Filling Machine is ideal for bulk filling of all types of non-viscous liquids in Glass, PET or other types of bottles. The machine is a low cost option for the small and medium scale industries. It is PLC controlled and the exact quantity of liquid required to be filled can be set. Quantity of liquid can be set from 50 ml to 2 liters. It is useful for filling liquids like Mineral Water, Milk, Juices, Liquid soaps, Medicines, Edible Oils etc. Hot filling is also possible.

The Machine consists of a long table on which the bottles can be kept in a line. There is a small tank on top of the machine with an automatic liquid level sensor and a pump. There is a control panel with a PLC to control the fill quantity and other features of the machine.

A brief method of using the machine:

- Switch on the machine.

- Calibrate the machine according to the viscosity of the liquid to be filled.

- This is a one time setting.

- Set the quantity of liquid to be filled.

- Switch on the pump. Liquid fills in the overhead tank.

- Align four bottles with the four filling nozzles and press a foot switch.

- The bottles are filled with the set quantity of liquid.

- Push the next batch of four bottles in place and press the switch and soon.

- Production can be anything between 8-16 bottles per minute depending on the quantity & viscosity of liquids and the speed of the operator

Advantages of the machine:

- Easy to use and requires very less maintenance.

- Flexibility of use to accommodate all types of liquids and bottles. The filling nozzles can be adjusted quickly according to the diameter and height of the bottles.

- Easy to clean after use.

- User friendly and does not require much training.

- The filling is controlled pneumatically and so an air compressor with a 1 Hp motor is required.

Semi Automatic Rotary Gravity Liquid Filling Machine – for PET / Glass Bottles

This is Rotary liquid filling machine meant for filling all non viscous liquids like Mineral Water, Juices, Edible oils, Coconut oil, Liquid soaps etc in PET & Glass bottles. As the machine rotates, bottles are manually kept for filling and taken off manually after filling.The machine has a 1 HP Geared motor controlled by a knob to reduce or increase RPM according to the size of bottles. It can fill any size from 200 ml to 2000 ml. Output will vary from 12 bottles per minute to 36 bottles per minute depending on the number of filling nozzles, size of bottle being filled, set RPM, viscosity of liquid and speed of the operator.

The machine consists of a rotating tank into which liquid can flow by gravity from an overhead storage tank or by a pump. The tank has a liquid level float valve. As it rotates, the operator places the bottles one after the other on neck holding plates in case of PET bottles and bottle tables in case of glass bottles. The bottles are filled automatically by gravity upto the nozzle level. After filling, the bottles can be manually removed for capping.

The machine is sturdily built and is made out of SS 304. It has a Panel to control the machine. The tank has a gage glass tube to monitor the level of liquid in the tank. It is easy to use and maintenance is limited to change in washers and springs of each valve which can be easily removed for cleaning and refitted quickly. The tank has a bottom drain to clean the tank whenever required

PET Bottle Capping Machine – Motorised

- This Capping Machine is used for capping PET bottles.

- Any PET bottle can be capped. However the capping die may vary according to the cap diameter.

- The Capper is powered by a 1/2 hP I PH motor with an attached gearbox.

- The capping die is fitted on the output shaft of the gearbox. The die rotates at an approximate speed of 100 RPM.

- After the PET bottle is filled, the cap is placed on it and the bottle with cap is pressed into the rotating Die.

- The rotating Die then automatically h olds the cap and tightens the cap on the bottle. This whole operation takes about 4-5 seconds depending upon the dexterity of the operator.

- A torque setting is provided to ensure the correct tightness of the cap. The amount of tightness required can be adjusted with the help of spring-loaded ball provided.

- The advantage of the machine is that all the bottles are evenly tightened and operator fatigue is low.

- An optional stand is available to fix the machine on a wall or table.

- About 10 bottles can be capped per minute.

PET Bottle Capping Machine – Pneumatic

This is an easy to use machine for capping plastic bottles – fast. It is very handy and portable and can cap about 10-12 bottles per minute depending on the user’s speed. It must be connected to an air compressor. An FRL must be fitted in the pipe from air compressor to the machine.

It has a torque setting which ensures that the cap is tightened exactly as much as required. The cap is placed on the bottle and the Pneumatic Capper is pressed on the cap. It is tightened and stops once the set torque is reached.

It’s unique features are:

- Being pneumatically operated , it requires very little maintenance except for oil in the FRL.

- Easy to use and requires very little skill.

- It is light weight and portable.

- Uses minimum quantity of air only when it is actually capping.

- No electrical connection and therefore free from short circuits and carbon brush problems.

Crown Capping Machine – Hand Operated Table Model – for Glass Bottles

This is a handy table top machine for crown corking glass bottles. It can be installed on a table and is easy to use.

A glass bottle is placed on the bottle table. The height of the crowning Die is adjusted to suit the bottle height. A crown is placed below the Die. It is held on by a magnet. The handle on the front is pressed downwards and the bottle is crowned.

The machine is robust and can crown about 7-8 bottles per minute depending on operator speed.

Crown Capping Machine Pneumatically Operated Table Model – for Glass Bottles

The machine is a table top model crown capping machine pneumatically operated. It can be installed on a table top.

The machine is connected to an air compressor. A crown is placed on the Die where it is held by a magnet. A bottle is placed on the bottle table and the hand lever is operated. After capping the bottle can be taken off for the next bottle. About 6-8 bottles can be capped per minute depending on the speed of the operator. Since it is pneumatically operated the bottles are crowned evenly and accurately. The pressure of crown capping can be set as required depending on the thickness & quality of the crown.

The machine is compact and portable. Air consumption is minimal and maintenance is limited to change of crowning Die when it gets worn out and change of oil in the FRL which controls the air quality and pressure from the compressor. The machine can cap glass bottles of all sizes from 200 ml to 750 ml.

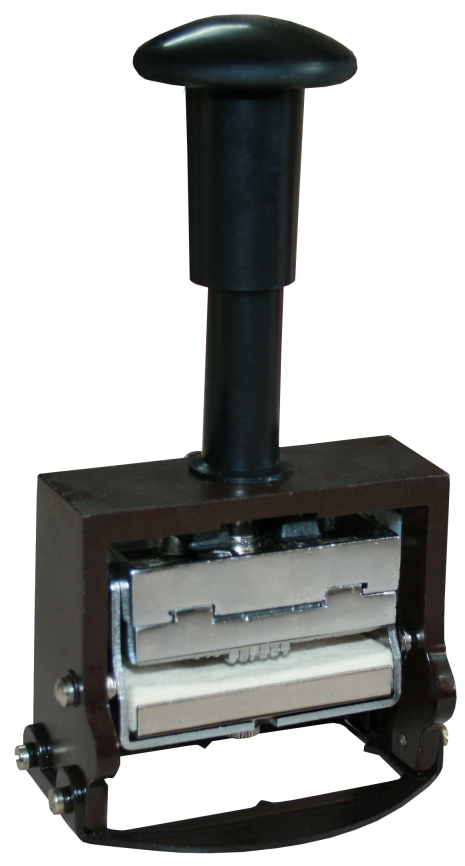

Hand Operated Batch Coding Machine – Manual

The Hand Operated Batch Coder is a handy machine for printing batch number, MRP, date of mfg etc as required. It can print three or four lines. The unit is available for printing on various surfaces like plastic, metal, wood, paper, ceramic and glass – on bottles, lids, caps, jars, labels, laminated cartons, tins, cups etc. It can print on flat and curved surfaces. For each application a model is available.

A complete set of alphabets, numbers and symbols are provided. These are available in sizes from 2mm to 10 mm depending on whether they are metallic or rubber. A bottle of special fast drying ink is supplied with the coder.

The machine is also supplied with a wooden base for printing on soda/soft drink glass bottles. It is also available pneumatically operated. The machine can be fitted on automatic Form Fill Seal Packing machines for printing on pouches as they are formed, filled and packed.

Dry Ink Coding Machine

This is a Semi automatic printing machine for statutory markings/coding on plastic/paperpouches, duplex boards/duplex cartons, labels etc. It is fast and easy to use.

A set of alphabets, numerals and symbols is provided with the machine. These are set on the print head and the printing can start. A set of labels or pouches are fed into the machine. It prints all the labels one after the other.

The Salient features of the machine are:

- High production speeds

- Pouches /labels can be fed in batches

- Uses hot melt ink

- No ink spillage

- No over inking

- Lower coding costs

- Easy to compose messages

- Equipped with Print counter & Photo electric sensor for position adjustment.

- Minimum maintenance.

Automatic Inkjet Coding Machine with Conveyor

This is an “ANSAR” make INKJET Coding Machine model PRO S for printing on porous & non-porous surfaces like PET, metal, plastic, wood & paper. It can be used for printing on bottles, caps, labels, boxes, bags etc.

It has the following unique features:

- Cartridge is suitable for 2.5 lakhs to 2.75 lakhs prints of three lines each which makes it extremely cost effective.

- Display of the printer of 3.5 inch LCD screen with LED back light

- User interface has a simple and easy to use operating system

- Input device is a pocket sized IR remote key pad

- Available languages are Chinese, English, German, Spanish etc,

- Size of the of the printer is 119 mm x 78.8 mm x 76.0mm

- Weight is 550 gms

- Mounting orientation can be horizontal or vertical

- Operating temperature is 5 degrees Celsius to 50 degrees Celsius

- Data interface is RS485, USB port

- Can be integrated with FFS machines, band sealers, taping machines and other packing machines for printing on labels, bags and pouches

The most significant advantage of the U2-ProS and TIJ printers in general is that they are virtually zero maintenance devices. Once a cartridge is exhausted, it merely has to be replaced with a new piece. There is no ink reservoir, make-up or complicated parts that need regular replacement like most large character or CIJ printers.

Shrink Wrap Tunnel All Purpose Economy Models – Floor Model

- Shrink-wrapping is one of the most popular and convenient forms of packaging.

- Shrink-wrap packaging involves the use of thermoplastic or thermosetting films that shrink when heat is applied to them.

- This machine is suitable for Shrink wrapping of all types of items like – individual or sets of bottles, labels on bottles, containers, packets etc.,

- It is a simple machine, easy to operate and requires no formal training.

- Once the machine is switched on and temperature is set, the shrink-wrapping can commence.

- The film is first wrapped / sealed around the product. It is then placed on the inlet of the machine. It goes in on a conveyor and comes out at the other end shrink wrapped.

- The heat tunnel size, price and other factors are governed by the product size.

Advantages of Shrink Wrapping are:

- Economical

- Protects the product from dust, moisture and humidity.

- It is a hygienic form of packaging for foodstuffs.

- Can be used for making multi packs and adds value to the product.

- Gives the product a good look and helps reduce pilferage

- Can be used to package any product of any size or shape.

- Shrink-wrapping material can be pre-printed.

The machines have the following unique features:

- Digital variable speed conveyor.

- Fan with special impeller for even heat circulation in the tunnel.

- Various models to suite your requirements.

- Separate control panel box for protection.

- Digital temperature controller.

- Silicon / Teflon covered roller.

Shrink Wrap Tunnel with Plastic Film Wrapper for – Packing PET Bottles

This is a Shrink Film Wrapper and Heat Shrinking Machine for packing PET Bottles. Shrink Wrapping is now a days considered a cheaper and better option in place of cardboard boxes.

The machine is in two parts – the Shrink Film Wrapper and the Heat Shrink Tunnel. The Wrapper has been provided with a set of guides to be adjusted according to the number and size of bottles to be packed. The Shrink Tunnel is provided with a metallic mesh conveyor to withstand temperature, suitable heaters, temperature sensor and controller to maintain the required temperature and a set of fans to circulate the heat inside the tunnel. The machine is controlled by a central control panel where the temperature inside the tunnel, the speed of the conveyor, the fans and other functions can be easily controlled.

The PET bottles are kept on a table on the Wrapper. The operator then presses a switch and the machine automatically wraps the shrink film over them. The bottles are now moved forwards by the machine. Meanwhile the operator can keep the next set of bottles. The first set of wrapped bottles now move into the shrink tunnel. The shrink wrapped bottles come out of the other end of the tunnel where another fan cools down the plastic film. The packed bottles are now taken off. The process continues as each set of bottles are placed one after the other.

The wrapping of the film takes place pneumatically and so an air compressor is required. It has height adjustable washers on each of its legs so the Wrapper and the Tunnel can be aligned on the same level. It has a set of holders on the top and at the bottom to hold the shrink film roll which have to be fixed.

The width of the film rolls will vary according to the number and size of bottles to be packed.

The machine has a sturdy powder coated MS body built for a long life. Both the Wrapper and Shrink Tunnel have wheels below so they can be moved easily. With minor adjustments that can be done quickly, PET bottles of any size from 200 ml to 2000 ml can be packed. Note that the machine can be used for other items like cardboard boxes, glass bottles, regular and irregular shaped objects etc can also be packed.

Labeling Machine – for PET / Glass Bottles

This is a compact table top self adhesive labelling machine for round PET and Glass Bottles. It can also be used for labelling round Cans / Tins. Ideal for small scale industries for quick & neat labelling. It is a simple machine to use.

The labels in roll form are loaded into the machine in the slot provided for this. One bottle is kept on the bottle table horizontally. When the handle is turned once, one bottle gets libeled. The machine can be used for bottles with different diameters and lengths.

The machine is made of powder coated mild steel and is sturdily built.It requires minimal maintenance. About 10-12 labels can be applied per minute depending on the operator’s speed.