Potato Chips Making Machines

Potato Peeling Machine

The Potato Peeler is a simple machine and easy to use.

The chamber of the machine, it’s lid and it’s revolving base are emery coated. The top cover of the peeling chamber is opened and about 2 kg of potatoes are poured in. The potatoes rub on the walls and are peeled. The peeled potatoes are removed from this chamber via the side door. The chamber has a nozzle fitted on the top lid to which a water connection is made to wash down the peeled skin from inside the chamber.

The machine is powered by a ½ Hp I ph Motor. The machine is robust and can be used continuously for 8 hours. About 500 – 600 kgs of potatoes can be peeled in 8 hours

Potato Chips Cutting Machine

The Cutting machine is simple and easy to operate. It is portable and can be installed on a table. It has a ½ Hp I ph motor.

Peeled potatoes are fed in through a pipe on the top of the machine. Plain Chips, finger chips or serrated chips come out the machine according to the blade used. The sliced pieces are ejected out of the chute. The chips are of even thickness.

The blades can be changed easily as required. An extra set of special blades are also available for cutting cubes of various sizes.

The machine can be quickly cleaned by opening the top lid. It is sturdy and robust and its cutting blade is made of SS 304 for a long life. It can also be used for vegetables like onions, carrots, radish etc.

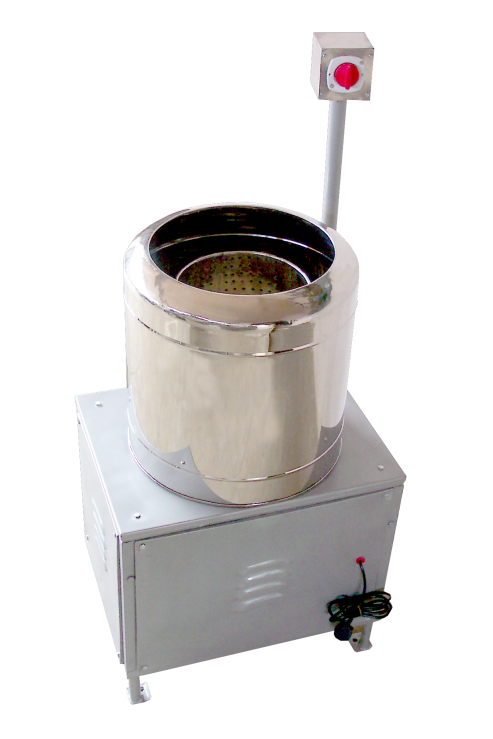

Potato Chips Dehydrating Machine

The Dehydrator is used for removing moisture from potato chips to make them crisp and crunchy when fried.

The machine removes most of the moisture in the potato chips. The sliced Potato chips are put into the Dehydration chamber. This contains a revolving stainless steel drum. When the timer switch is turned on, the high speed revolution of the drum helps remove moisture from the product by the process of spin drying. After the set time, the drum stops revolving and the dried chips can be now taken out for frying.

The drying chamber is made of SS 304. It can be taken out for cleaning. The outer chamber in which the water is collected has a bottom drain to remove it. The machine has a ½ Hp I ph motor and needs very little maintenance. It can process about 500 – 600 kgs per 8 hours.

Potato Chips Frying Machine

The Potato Chips Fryer is basically a frying vessel with a burner to be connected to an LPG cylinder. About 3 kgs of potato chips can be fried at one time. Oil capacity of the vessel is approximately 15 – 20 liters which can be refilled as it is consumed

Continuous Plastic Bag Band Sealing Machine -Table Model – with Nitrogen Packing

The Continuos Band Sealer is ideal for packaging requirements of many industries. It is a rugged and ideal machine for packing of potato chips, dry fruits etc with nitrogen gas flushing.

Its salient features are:

- Adjustable temperature / PID controller models

- suitable for a vide spectrum of materials.

- Variable speed conveyor.

- Vertical/Horizontal mountable models.

- Optional embossing facility on sealing on select models.

- Conveyor Speed: 0~12 m/min.

- Max Conveyor load: 3 Kgs.

- Models for all types of materials including virgin materials.

- Construction (body) in SS or MS powder coated.