Packaging Machines

Hand Operated – Plastic Bag Sealing Machine

This Machine is ideal for heat sealing plastic bags, multi layer pouches, laminated pouches etc. It can seal bags of various lengths and widths. It is very easy to use.

The bag with its contents is held between the sealing jaws and the handle pressed. An adjustable timer is provided to set the sealing time to suit the thickness of the bag being sealed. The machine heat seals the mouth of the bag. It can be used for packing food grains, dry fruits, granules, powders and all those things that need to be packed in plastic bags. It is an ideal machine for shops, bakeries, department stores, food packers and industries where packing is required.

Many models of the machine are available to suit various packing requirements. The main options available are:

- Various sealing lengths

- Various sealing widths

- Impulse or Hot bar sealing

- With sealing and cutting option

The salient features of this machine are:

- For heat sealing poly pouches

- Hand Operated

- Adjustable electronic timer

- Audio & visual sealing indicators

- Suitable for packing solids, granules and powders

- Round element option for sealing and cutting

Foot Operated Plastic Bag Sealing Machine

This Machine is ideal for heat sealing plastic bags, multi layer pouches, laminated pouches etc. It can seal bags of various lengths and widths. It is very easy to use.

The bag with its contents is held between the sealing jaws and the foot pedal pressed. An adjustable timer is provided to set the sealing time to suit the thickness of the bag being sealed. The machine heat seals the mouth of the bag. It can be used for packing food grains, liquids, dry fruits, granules, powders and all those things that need to be packed in plastic bags. It is an ideal machine for shops, bakeries, department stores, food packers and industries where large volumes of packing is required.

Many models of the machine are available to suit various packing requirements.

The main options available are:

- Various sealing lengths

- Various sealing widths

- Impulse or Hot bar sealing

- Tilting or non tilting head sealer

- With sealing and cutting option

- For liquids and non liquids

Continuous Plastic Bag Band Sealing Machine -Table Model

The Continuous Sealer is ideal for large scale plastic bag/pouch sealing useful for packing Food grains, powders, cereals, tea etc. They are ideal for packaging requirements of many industries.

Salient Features:

- Adjustable temperature / PID controller models suitable for a vide spectrum of materials.

- Variable speed conveyor.

- Vertical/Horizontal mountable models.

- Optional embossing facility on sealing on select models.

- Conveyor Speed: 0~12 m/min.

- Max Conveyor load: 3 Kgs.

- Models for all types of materials including virgin materials.

- Construction (body) in SS or MS powder coated.

Continuous Plastic Bag Band Sealing Machine -Table Model with Nitrogen Packing

The Continuous Band Sealer is ideal for packaging requirements of many industries. It is a rugged and ideal machine for packing of potato chips, dry fruits etc with nitrogen gas flushing.

Salient Features:

- Adjustable temperature / PID controller models suitable for a vide spectrum of materials.

- Variable speed conveyor.

- Vertical/Horizontal mountable models.

- Optional embossing facility on sealing on select models.

- Conveyor Speed: 0~12 m/min.

- Max Conveyor load: 3 Kgs.

- Models for all types of materials including virgin materials.

- Construction (body) in SS or MS powder coated.

Continuous Plastic Bag Band Sealing Machine – Heavy Type

The Continuous Sealer is ideal for large scale plastic bag/pouch sealing useful for packing Food grains, powders, cereals, tea etc. They are ideal for packaging

requirements of many industries.

The machine has a heavy duty conveyor and band sealer specially meant for packing heavy bags which may not be possible to seal on table top machines.

The salient features of the machine are:

- Adjustable temperature / PID controller models suitable for a wide spectrum of materials.

- Variable speed conveyor.

- Sealing width up to 10 mm.

- Optional embossing facility on sealing on select models.

- Conveyor Speed: 0~12 m/min.

- Max Conveyor load: 15 Kgs.

- Vertical model so that the bags are sealed in the standing position.

- Models for all types of materials including virgin materials.

- Construction – MS powder coated.

Gas / Air Flushing Continuos Plastic Bag Band Sealing Machine

This is an ideal machine for packing plastic bags with air / gas flushing inside the bag before sealing. This is a portable machine. Plastic bags of all sizes can be sealed on it. It’s main purpose is to fill air/gas inside before sealing it thus protecting its contents and in case of food items, also extends its shelf life.

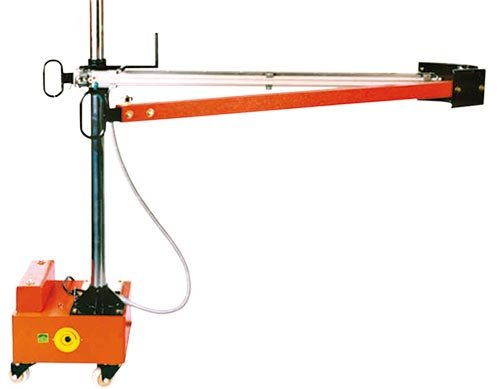

Mobile Sealing Machine

This machine is exclusively for sealing heavy bags. Ideal for packing tea, chemicals, food items, grains, powders etc.

The machine can be wheeled to the bag and sealing can be done on the spot. The height of the sealing jaws can be adjusted from 0.3 meters to 1.3 meters according to the height of the bag to be sealed.

The sealing is impulse type and so the machine does not consume energy continuously. The sealing length is 900 mm and sealing width 5 mm.

Tong Type Sealing Machine

The main advantage of this machine is that it is portable and can be taken to the object to be sealed.

The salient features of this machine are:

- Sealing possible at difficult angles.

- Provision for belt; to suspend from shoulder or ceiling.

- Ideal for sealing heavy plastic bags, mattresses,’machinery, etc.

- Adjustable electronic timer.

- Visual indication during sealing.

- Audio indication at the end of sealing.

Technical Specification

| Model 400T | (Seal mm) | Power | Dimensions (mm) Weight | |||||

|---|---|---|---|---|---|---|---|---|

| Length | Width | V | W | L | B | H | Kg | |

| Base Unit | – | – | 240 | 140 | 250 | 140 | 175 | 5 .5 |

| Tong Unit | 400 | 1.6 | 240 | 450 | 525 | 350 | 215 | 3 |

Hot Air Gun

Heat Shrink tubing, removing paint and de-freezing frozen pipes are just some of the jobs that can be easily done with these hot air guns. The gun fulfills all requirements of a modern and risk free use of heat guns.

The 2-stage step switch for temperature 300 Deg C (550 Deg F) to 500 Deg C (900 Deg F) and airflow, joined with an assortment of plug-on nozzles complete the unit. The light weight, simple to handle body style makes working with it very easy.

Vacuum Packing Machine Table Top and Floor Models

- Stainless steel vacuum chamber, Transparent lid for observation

- Machines are available with different chamber sizes for packing different sizes of bags.

- Production depends on chamber and bag sizes.

- Provision for measurement & control of vacuum.

- Impulse heat sealing system with electronic timer /audio / visual indicators.

- Vacuum packing increases shelf life of perishables, retains aroma, prevents moisture absorption and oxidation.

- Recommended for packing fish, meat products, cashew nuts, dry fruits, tea, sensitive electronic components & electrodes.

- Control panel conveniently located in front of machine

Shrink Wrap Tunnel – for Labels

This Shrink Tunnel is meant for label shrinking on PET Bottles. It is made of SS 304 and is sturdily built for long life. The tunnel has a SS Slat chain conveyor.

The size of the tunnel is 4” wide x 15” height. Heaters are provided inside. A temperature sensor, temperature controller, heat circulation fans and conveyor speed control are provided. All the functions of the tunnel can be controlled from the control panel provided on top of the machine.

The main features of the machine are:

- Intelligent shrink temperature control

- Conveyor speed is adjusted by step less adjuster

- Unique conveyor device to ensure stable transmission

Shrink Wrap Tunnel – All Purpose Economy Model – Table Top

- This machine is suitable for Shrink wrapping of all types of items like – individual or sets of bottles, labels on bottles, containers, packets etc.,

- It can be installed on a table.

- It is a simple machine, easy to operate and requires no formal training.

- Once the machine is switched on and temperature is set, the shrink-wrapping can commence.

- The film is first wrapped/sealed around the product. It is then placed on the inlet of the machine. It goes in on a conveyor and comes out at the other end shrink-wrapped.

- The heat tunnel size, price and other factors are governed by the product size.

The main advantages of Shrink Wrapping are:

- Economical

- Protects the product from dust, moisture and humidity.

- It is a hygienic form of packaging for foodstuffs.

- Can be used for making multi packs and adds value to the product.

- Gives the product a good look and helps prevent pilferage

- Can be used to package any product of any size or shape.

- Shrink – wrapping material can be pre-printed.

The machines have the following unique features:

- Digital variable speed conveyor.

- Fan with special impeller for even heat circulation in the tunnel.

- Various models to suite your requirements.

- Separate control panel box for protection.

- Digital temperature controller.

- Silicon / Teflon covered roller.

Shrink Wrap Tunnel All Purpose Economy Models – Floor Model

- This machine is suitable for Shrink wrapping of all types of items like – individual or sets of bottles, labels on bottles, containers, packets etc.,

- It is a simple machine, easy to operate and requires no formal training.

- Once the machine is switched on and temperature is set, the shrink-wrapping can commence.

- The film is first wrapped / sealed around the product. It is then placed on the inlet of the machine. It goes in on a conveyor

- and comes out at the other end shrink wrapped.

- The heat tunnel size, price and other factors are governed by the product size.

Advantages of Shrink Wrapping are:

- Economical

- Protects the product from dust, moisture and humidity.

- It is a hygienic form of packaging for foodstuffs.

- Can be used for making multi packs and adds value to the product.

- Gives the product a good look and helps reduce pilferage

- Can be used to package any product of any size or shape.

- Shrink-wrapping material can be pre-printed.

The machines have the following unique features:

- Digital variable speed conveyor.

- Fan with special impeller for even heat circulation in the tunnel.

- Various models to suite your requirements.

- Separate control panel box for protection.

- Digital temperature controller.

- Silicon / Teflon covered roller.

Shrink Wrap Tunnel with Plastic Film Wrapper for – Packing PET Bottles

This is a Shrink Film Wrapper and Heat Shrinking Machine for packing PET Bottles. Shrink Wrapping is now a days considered a cheaper and better option in place of cardboard boxes.

The machine is in two parts – the Shrink Film Wrapper and the Heat Shrink Tunnel. The Wrapper has been provided with a set of guides to be adjusted according to the number and size of bottles to be packed. The Shrink Tunnel is provided with a metallic mesh conveyor to withstand temperature, suitable heaters, temperature sensor and controller to maintain the required temperature and a set of fans to circulate the heat inside the tunnel. The machine is controlled by a central control panel where the temperature inside the tunnel, the speed of the conveyor, the fans and other functions can be easily controlled.

The PET bottles are kept on a table on the Wrapper. The operator then presses a switch and the machine automatically wraps the shrink film over them. The bottles are now moved forwards by the machine. Meanwhile the operator can keep the next set of bottles. The first set of wrapped bottles now move into the shrink tunnel. The shrink wrapped bottles come out of the other end of the tunnel where another fan cools down the plastic film. The packed bottles are now taken off. The process continues as each set of bottles are placed one after the other.

The wrapping of the film takes place pneumatically and so an air compressor is required. It has height adjustable washers on each of its legs so the Wrapper and the Tunnel can be aligned on the same level.

It has a set of holders on the top and at the bottom to hold the shrink film roll which have to be fixed. The width of the film rolls will vary according to the number and size of bottles to be packed.

The machine has a sturdy powder coated MS body built for a long life. Both the Wrapper and Shrink Tunnel have wheels below so they can be moved easily. With minor adjustments that can be done quickly, PET bottles of any size from 200 ml to 2000 ml can be packed. Note that the machine can be used for other items like cardboard boxes, glass bottles, regular and irregular shaped objects etc can also be packed.

L Sealers

- Adjustable platform height to accommodate varying package size

- Adjustable platform to ensure optimum sealing & cutting Film separator.

- Film roll stand, film puncturing device

- Film separator easily separates layers of the folded film roll & also serves as a loading table.

- Film separator can be moved to suit film rolls of different widths

| Model | Seal (mm) | Power | Dimensions (mm) | Weight | |||

|---|---|---|---|---|---|---|---|

| V | KW | L | B | H | Kg | ||

| L 4050 | 400 x500 | 240 | 900 | 1390 | 600 | 1050 | 70 |

| L 5060 | 500 x600 | 240 | 1200 | 1490 | 700 | 1050 | 85 |

Box Strapping Machine

Semi Automatic Strapping machines are used for binding paper cartons, wooden boxes etc. using PP straps.

The machine automatically tensions the strap around the box and joins both ends of the strap by heat seal. High Table ( HT ) & Low Table (LT ) models are available to suit different product line requirements.

Aluminum Foil Sealing Machine – Manual

This machine is ideal for sealing plastic coated aluminum foils on PET bottles, plastic cups & jars. It has a heater with temperature controller. The cups or bottle with the foil on it is placed on the machine and the handle pressed. The hot sealing plate melts the plastic coating on the foil and seals it on the rim. The machine is compact and can be installed on a table.

Various diameters of aluminum foil can be sealed

Semi Automatic Cup Sealing Machine

This Cup sealer is a convenient machine for sealing plastic film on cups. It is semi automatic and easy to operate:

- The filled cup is placed inside the cup holding Die.

- The tray holding the Die is pushed inside the machine and a handle is pressed.

- The machine presses the pre-loaded laminated foil (Roll) on the cup and seals and cuts the outer rim of the film.

- The tray is pulled out and the cup is removed.

- The process is repeated for the next cup.

- The approximate speed of the machine is 250 cups / hour.

The machine is available with the following options

- For various cup diameters

- Two / four cups can be sealed at a time

- Automatic type available.

Semi Automatic Rotary Juice Filling & Plastic Cup Foil Sealing Machine

This is an ideal machine for liquid filling and sealing of plastic cups. It fills, places the foil, seals it and ejects the cups. It has a rotary table with multiple cavities in which the cups are placed manually or can be placed automatically by the machine itself. As the table rotates, the liquid is filled, the foil is placed, sealed and the cup ejected one after the other.

The machine is controlled by a PLC and the fill quantity, sealing time, sealing temperature etc can be set as required. The production of the machine can vary from 12 cups/minute to about 30 cups/minute. The machine is constructed of SS 304 and is user friendly.