Capping Machines

PET Bottle Capping Machine – Motorized

- This Capping Machine is used for capping PET bottles.

- Any PET bottle can be capped. However the capping die may vary according to the cap diameter.

- The Capper is powered by a 0.25 hP I PH motor with an attached gearbox.

- The capping die is fitted on the output shaft of the gearbox. The die rotates at an approximate speed of 100 RPM.

- After the PET bottle is filled, the cap is placed on it and the bottle with cap is pressed into the rotating Die.

- The rotating Die then automatically holds the cap and tightens the cap on the bottle. This whole operation takes about 4-5 seconds depending upon the dexterity of the operator.

- A torque setting is provided to ensure the correct tightness of the cap. The amount of tightness required can be adjusted with the help of spring-loaded ball provided.

- The advantage of the machine is that all the bottles are evenly tightened and operator fatigue is low.

- An optional stand is available to fix the machine on a wall or table.

- About 10 bottles can be capped per minute.

PET Bottle Capping Machine – Pneumatic

This is an easy to use machine for capping plastic bottles – fast. It is very handy and portable and can cap about 10-12 bottles per minute depending on the user’s speed. It must be connected to an air compressor. An FRL must be fitted in the pipe from air compressor to the machine.

It has a torque setting which ensures that the cap is tightened exactly as much as required. The cap is placed on the bottle and the Pneumatic Capper is pressed on the cap. It is tightened and stops once the set torque is reached.

It’s unique features are:

- Being pneumatically operated , it requires very little maintenance except for oil in the FRL.

- Easy to use and requires very little skill.

- It is light weight and portable.

- Uses minimum quantity of air only when it is actually capping.

- No electrical connection and therefore free from short circuits and carbon brush problems.

Crown Capping Machine – Hand Operated Table Model – for Glass Bottles

This is a handy table top machine for crown corking glass bottles. It can be installed on a table and is easy to use.

A glass bottle is placed on the bottle table. The height of the crowning Die is adjusted to suit the bottle height. A crown is placed below the Die. It is held on by a magnet. The handle on the front is pressed downwards and the bottle is crowned.

The machine is robust and can crown about 7-8 bottles per minute depending on operator speed.

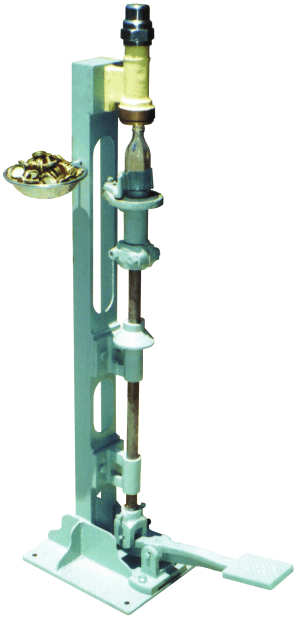

Crown Capping Machine Foot Operated – Floor Model for Glass Bottles

The Foot Operated Crowner is ideal for crown capping glass bottles. It can cap bottles from 200 ml to 1000 ml. For this the height of the bottle table can be adjusted. It is easy to install and use. The stand is made of MS. The Capping head is of Gunmetal. The machine is very sturdy.

One Crown is inserted into the filling head. A bottle is placed on the bottle table. The foot pedal is pressed and the bottle gets capped. The capped bottle is removed and the next one is placed. Fast and accurate capping are its main advantages. About 300 – 350 bottles can be capped per hour depending on the dexterity of the operator. The machine is available as Hand or Pneumatically operated also.

Crown Capping Machine Pneumatically Operated Floor Model – for Glass Bottles

This is a Pneumatically Operated Crown Capping Machine for glass bottles. It can be used to cap glass bottles from 200 ml to 1000 ml. The bottle table can be adjusted according to the size of bottle to be capped. An air compressor of 1 HP is required. The machine has a rigid MS stand and is very sturdy. The pneumatic components used are of the best quality. It is easy to install and use.

One crown is inserted into the filling head. A bottle is placed on the bottle table. Then the pneumatic foot switch is pressed to cap the bottles. Since the machine is pneumatic, the capping pressure can be set to get fast and accurate capping. About 300 – 350 bottles can be capped per hour depending on the dexterity of the operator. The machine is available as hand or foot operated also.

Crown Capping Machine Pneumatically Operated Table Model – for Glass Bottles

The machine is a table top model crown capping machine pneumatically operated. It can be installed on a table top.

The machine is connected to an air compressor. A crown is placed on the Die where it is held by a magnet. A bottle is placed on the bottle table and the hand lever is operated. After capping the bottle can be taken off for the next bottle. About 6-8 bottles can be capped per minute depending on the speed of the operator. Since it is pneumatically operated the bottles are crowned evenly and accurately. The pressure of crown capping can be set as required depending on the thickness & quality of the crown.

The machine is compact and portable. Air consumption is minimal and maintenance is limited to change of crowning Die when it gets worn out and change of oil in the FRL which controls the air quality and pressure from the compressor. The machine can cap glass bottles of all sizes from 200 ml to 750 ml.

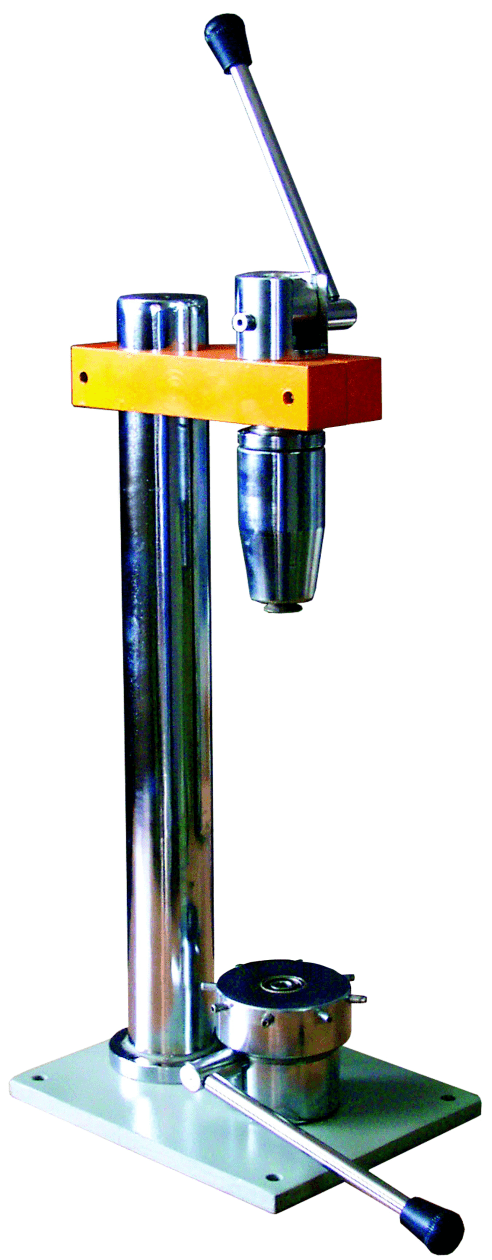

Pilfer Proof Capping Machine Manually Operated

This machine is designed for fast and accurate threading and sealing of pilfer proof metal caps used mainly in the food, pharmaceutical & other industries. The machine can be installed on a table. The construction and use being simple, it requires very little skill of operation.

The method of use is:

- Place the cap on the bottle.

- Place the bottle with cap on the bottle table by pressing lever below table.

- The bottle is now locked between the bottle table and the capping Die.

- Rotate the handle of wheel on the right hand side of the machine clockwise.

- At the same time press the handle on the left hand side of the machine towards the cap.

- First press the threading roller on the cap and then the sealing roller.

- The capped bottle can be taken off by once again pressing the handle below table.

- Repeat the process for the next bottle.

The machine is supplied with various sizes of Dies to suit various cap diameters. About 2-3 bottles can be capped per minute depending on the speed of the operator. This machine is available as a Pedestal model also which is motorized and easier to use.

Pilfer Proof Capping Machine Motorised

This is a versatile ROPP Cap Sealer, sealer which can be used for sealing and threading metal cap on PET and glass bottles. Bottles of various heights, shapes, sizes and mouth diameters can be capped. It has a ½ HP motor which rotates the Die. It is easy to install and use.

Press the foot pedal and place one bottle on the bottle table. When the foot pedal is released the bottle gets locked between the bottle table and capping die and it automatically threads and seals the cap. Press foot pedal once gain to remove the bottle. About 180-200 bottles can be capped per hour depending on the speed of the operator.

The machine has an MS stand and is sturdily built. Dies of various sizes are provided so caps of different diameters can be sealed. A height adjustment rod is provided to suit bottles of different heights. The machine requires very little maintenance.

Lug Cap Sealing Machine – Manually Operated

This is a light weight easy to use manually operated machine used for capping bottles of Pickles, Jam, Sauces, Juices etc. Bottles with various mouth sizes & heights can be sealed.

The method of operation is simple. Filled bottles with cap on top is placed on the bottle table. The top hand lever is pressed. Capping handle is turned 45 degrees for capping.

A production of about 5-6 bottles per minute can be achieved depending on the dexterity of the operator.

The salient features of the machine are:

- Convenience of usage

- Minimum maintenance.

- The Capping Die is Stainless steel.

- It is light weight and easy for transportation

Lug Cap Sealing Machine – Pneumatically Operated

This is pneumatically operated machine used for capping glass bottles of Pickles, Jam, Sauces, Juices etc. Bottles with various mouth sizes & heights can be sealed.

The method of operation is simple. Filled bottles with cap on top is placed on the bottle table. Pneumatic foot switch or hand lever is pressed. The capping head presses on the cap. Capping handle is turned 45 degrees for capping. A production of about 5-6 bottles per minute can be achieved depending on the dexterity of the operator.

An air compressor is required. A hand operated model is also available.

The salient features of the machine are:

- Convenience of usage

- Minimum maintenance.

- Good quality pneumatic spares used for longer life.

- Capping Die is stainless steel.

- Easy availability of spare parts and therefore lesser downtime.

- Is light weight and easy for transportation

Induction Sealing Machine – Hand Operated

The Induction Sealer is a simple machine to heat seal foils on top of plastic bottles.

The method of use is simple:

- Place the foil with wad on top of the bottle and screw the cap tight.

- Place the sealer’s portable sealing unit on top of the tightened cap.

- Press the red switch on top of the sealer unit for a few seconds.

- The foil inside is heated and sealed on to the plastic bottle by electromagnetic induction

Sealing is over – take off the unit. - Repeat for the next bottle.

Features:

- Employs the principle of electro magnetic induction.

- Simple in operation, air cooled.

- Convenient torch unit.

- Ideal for small production.

- Economically priced .

- A Semi automatic machine with conveyor is also available for continuous bulk production.

Induction Sealing Machine – Continuous with Conveyor

The Continuos Induction Sealer is a simple machine to heat seal foils on top of plastic bottles.

The method of use is simple:

- Install the machine on a table top.

- Place the foil with wad on top of the bottle and screw the cap tight.

- Place the bottle on the conveyor.

- When the bottle moves below the sealing section, the foil inside is heated and sealed on to the plastic bottle by electromagnetic induction Take off the bottle after sealing at other end of the conveyor.

- Bottles can be placed continuously one after the other for fast and easy sealing.

- The output of the machine depends on the speed the bottles are placed.

Features:

- Employs the principle of electro magnetic induction.

- Simple in operation, air cooled.

- Ideal for large production.

- Economically priced .

- A hand operated model is also available.

Vial Cap Crimping & Decrimping Machine – Hand Operated

The Hand Held Crimping machine is an indispensable tool for hospitals, pharmaceutical companies, research institutes, labs etc for crimping vial caps.

The machine is hand operated. It gives perfect and tight vial cap sealing. The working parts of the Crimper are hardened steel. The machine is strongly built and is light weight and easy to use. Just place it on the cap to be crimped and press the two levers together like a cutting plier for crimping on the bottle. About 8-10 bottles can be capped per minute depending on the speed of the user.

It is available in mild steel body or full stainless steel body

Unique Features:

- An indispensable tool for Hospitals, Research Institutes, Ayurvedic Concerns, Pharmaceutical Industries & Allied Traders.

- Gives perfect & tight vial sealing.

- Smooth operation.

- It can be used for either small or large production.

- Strongly built body & light in weight.

- Hardened working parts.

- Available in mild steel – chrome plated body as well as in stainless steel body.

- Very simple operation.

- The machine can be held in the hand very easily in its open position.

Drum Cap Sealing Machine Hand Operated

These drum capping tools are used extensively to cap 200 liter (50 gallon) drums that are utilized to store and transport chemicals, pharmaceutical raw materials and commodities like crude oil.

The drum capping tool is meant for caps of two diameters – 3/4” and 2”. Depending on operator speed this tool can secure anywhere between 240-360 caps per hour. The body is made out of mild steel with nickel-chrome plating and the jaws are made of heat treated mild steel.

The sealers are easy to use and require very less maintenance.

Newman Cap Sealing Machine – Hand Operated

The Newman Cap Sealer is a hand operated tool for seaming the lids on Cans, Tins and Drums used in the edible oil and other industries. Being light in weight, it is easy to use and portable.

Place the lid on the mouth of the Tin or Can to be sealed. Place the sealer on the lid. Press the handle down and twist the machine 360 degrees. To ensure a proper crimping, turn the machine twice or thrice. The machine is made out of mild steel and its crimping rollers are hardened.

Can Double Seaming Machine – Motorised – Table Model

This is a compact table top Tin Lid Double Seaming Machine for Metal & Plastic Cans.

It is easy to use. The filled can with the lid is placed on the table and the seaming switch is pressed. The table with the Can goes up into the seaming head and the two seaming rollers seam the lid in two layers – one after the other. The seamed Can, can be removed and the next one is placed.

The machine requires very little maintenance. The seaming head can be custom made to suit the lid diameter. Cans of different diameters and heights can be seamed. About 6 Cans can be seamed in a minute depending on the speed of the operator. The machine has a 1/2 Hp I ph motor.

Can Seaming Machine – Motorised

The machine is designed for double seaming of Can lids. It is powered by a 1 Hp III ph motor and can seam about 600 Cans per hour depending on the dexterity of the operator. It is easy to operate

- Person presses the hand lever in front of the machine down and places the Can with lid on the Can table.

- The hand lever is then pressed up and the lid goes into the Chuck.

- The Can with lid is rotated with the chuck and Can table, and the double seaming rollers seam the lid on the Can.

- The front lever is again pressed down and the Can removed.

It is mounted on a solid MS frame and all its parts are designed and manufactured for a long working life. It requires very little maintenance and can be used for 8-10 hours daily. The machine is available with most sizes of standard Flanging Dies.

Aerosol Can Crimping Machine – Hand Operated

- This machine is used for crimping Aerosol Cans.

- It is a simple machine to use.

- The cap to be crimped with the valve is placed on the mouth of the filled Can.

- The height adjustment is made according to the height of the Can.

- The handle is then pressed.

- The Crimping Collet opens and crimps the cap.

- The Can is removed rom the machine.

- Any Can may be crimped. The Collet is suitable for 25 mm cap.

- An average production of about 6 Cans per minute can be achieved. However, this depends on the dexterity of the operator.

- The Machine can be supplied pneumatically operated also.