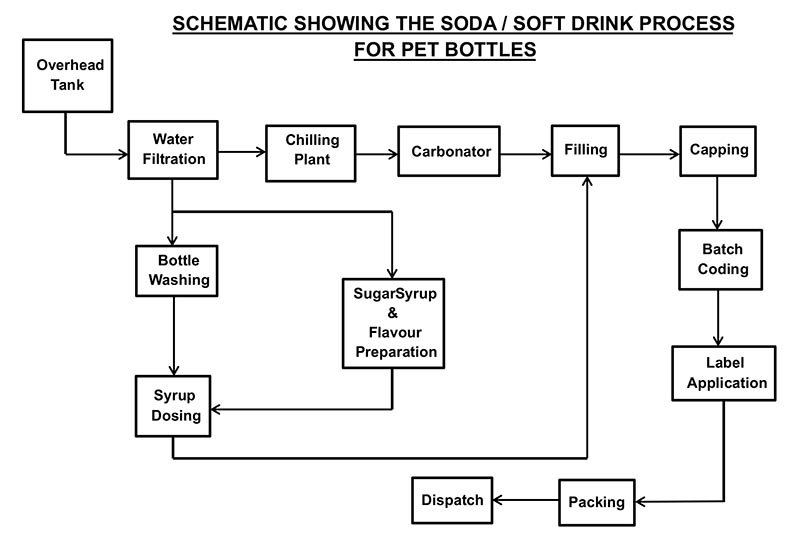

Soda/Soft Drink Machines for Pet Bottles

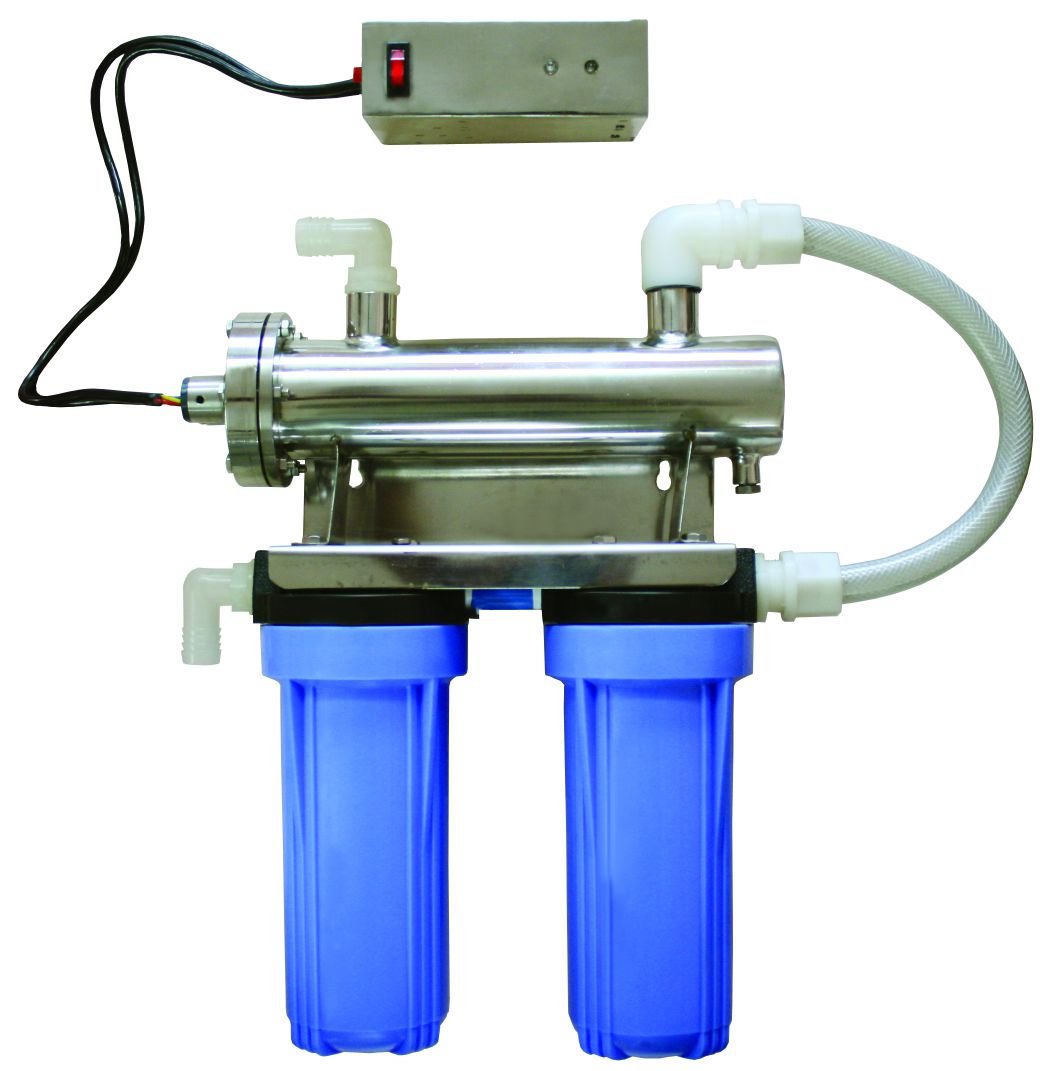

Ultra Violet Water Filter

Ultra Violet Water Filter System is ideal for filtration of Bore well and Well water. It is a 3-in-1 filter system.

It has a 10 micron filter cartridge which removes all visible dust particles. The water then flows through an activated Carbon Cartridge which removes chemicals and odour. Then the water flows through the UV chamber where two UV lamps are provided. They help to eliminate bacteria , germs, pathogens etc.

The filter can process about 500 litres of water per hour. It can be connected to an overhead tank and the water will flow through it by gravity. There is no need for pumps.

It is wall mountable and easy to assemble. It requires very little maintenance and is user serviceable.

It is an ideal unit for Soda / Soft drink makers, juice processing factories, hostels, hotels, etc. and wherever bulk drinking water is required.

Sand Water Filter

The Sand Water Filter is used for filtering out all visible dust particles from water. To a certain extent, It also removes chemicals and odour from water.

The filter is made of Fibre Reinforced Plastic (FRP) and is therefore maintenance free. The FRP material is ideally suited for water filtration tanks and is very strong and rigid. The tank requires no painting and does not rust.

Water passes through three layers of special Quartz stones and sand and a layer of Activated Carbon. A 10 micron filter cartridge is also provided at its outlet to remove tiny dust particles.

A system of pipes and ball valves is provided which are attached to the main portion of the tank. The filter can be connected to an overhead tank and the water flows through the filter by gravity. About 500 litters of water can be filtered per hour.

Other than periodic backwash and a change of carbon, the filter requires very little maintenance.

It is an ideal unit for Soda /soft drink makers, juice processing factories, Hostels, Hotels etc and wherever bulk drinking water is required.

Reverse Osmosis Filter Unit

Reverse Osmosis is a technology that is used to remove a large majority of contaminants from water by pushing the water under pressure through a semipermeable membrane. The unit consists of a comprehensive set of filters like –

- Prefilter to remove dust

- Carbon filter to remove chemicals and other off smells

- Ultra violet lamps to kill harmful bacteria and viruses

- Reverse Osmosis filter unit to remove contaminants

- Ozonator (Optional)

- Other filters can be added depending on the inlet water quality.

The whole unit is mounted on a skid so it is easy to transport and can be quickly installed. Each filter unit is connected to the next in line with necessary pipes and fittings. Pumps are also provided.

The different filter stages are selected depending on the quantity of water available and so a Water Test Report is essential. Based on the report, the system can be tailored to get best results.

The unit is easy to install and requires minimum maintenance. It is made for reliable performance.

Water Chilling Plant 200 / 300 Liters per hour

Chilled water is an absolute necessity for soda/soft drink making ensuring better carbonation. Our Chilling plant is ideal for cooling water from ambient/room temperature to about 4-5 degrees Celsius.

It is designed for better efficiency to save on power and temperature loss. It as a refrigeration system and cooling tank consisting of an inner tank and outer cover which are both made of SS 304. Sufficient Thamacol insulation is done between them to prevent loss of temperature thus improving the efficiency of the Chiller. Water inlet and outlet connections are conveniently provided for easy installation and piping. A temperature indicator is also provided to monitor outlet temperature. The Chiller with its tank and refrigeration system are assembled in a single unit so it is easy for packing, transportation and immediate start up at user end.

The Chiller is available in various capacities as follows:

| Output / Hour | No. of Compressors | Tons |

|---|---|---|

| 200 LPH | 1 | 2 |

| 300 LPH | 2 | 4 |

Water Chilling Plant 500 / 750 Liters per hour

Chilled water is an absolute necessity for soda/soft drink making ensuring better carbonation. Our Chilling plant is ideal for cooling water from ambient/room temperature to about 4-5 degrees Celsius.

It is designed for better efficiency to save on power and temperature loss. It has a refrigeration system and cooling tank consisting of an inner tank and outer cover which are both made of SS 304. Sufficient Thamacol insulation is done between them to prevent loss of temperature thus improving the efficiency of the Chiller. Water inlet and outlet connections are conveniently provided for easy installation and piping.

A temperature indicator is also provided to monitor outlet temperature. The Chiller with its tank and refrigeration system are assembled in a single unit so it is easy for packing, transportation and immediate start up at user end. The Chiller has a control panel mounted in the front from where the Compressors can be switched on & off, the input voltage can be monitored and the main switch turned on.

The Chiller is available in various capacities as follows:

| Output / Hour | No. of Compressors | Tons |

|---|---|---|

| 500 LPH | 3 | 6 |

| 750 LPH | 4 | 8 |

Carbonator – Small

This Carbonator is ideal for small scale soda/soft drink companies. It is of simple construction, hence maintenance and cleaning are very easy. Due to its special internal construction, quality of soda is high & better gas volumes can be achieved.

CO2 gas is fed into the carbonator through a Pressure Regulating Valve from the bottom. A highly efficient three piston pump feeds the carbonator with water. The pump has high quality durable seals that ensures very low maintenance of the pump. Water is fed by the pump to the carbonator from the top. Inside, there is a shower & a series of SS Plates mounted one on top of the other. The water is showered inside the carbonator and trickles down the plates. This ensures thorough saturation. The whole assembly is mounted on a SS stand. An Automatic Liquid Level Controller is also fitted to switch the motor on or off according to the level of water inside the tank.

The Pump and motor are fitted below the tank and covered on three sides to protect them from getting wet.

The size of the carbonator is 5” diameter x 2.5 ft height and output capacity is about 450 LPH.

Carbonator – Medium

This Carbonator is ideal for small scale soda/soft drink companies. It is of simple construction, hence maintenance and cleaning are very easy. Due to its special internal construction, quality of soda is high & better gas volumes can be achieved.

Co2 gas is fed into the carbonator through a Pressure Regulating Valve from the bottom. A highly efficient three piston SS pump feeds the carbonator with water. The pump has high quality durable seals that ensures very low maintenance of the pump. Water is fed by the pump to the carbonator from the top. Inside, there is a shower & a series of SS Plates mounted one on top of the other. The water is showered inside the carbonator and trickles down the plates. This ensures thorough saturation. The whole assembly is mounted on a SS stand. The carbonator is pre-insulated to preserve water temperature. An Automatic Liquid Level Controller is also fitted to switch the motor on or off according to the level of water inside the tank.

The Pump and motor are fitted below the tank and covered on three sides to protect them from getting wet.

The size of the carbonator is 8” diameter x 3.5 ft height and output capacity is about 650 LPH. It can be altered for premix carbonation also.

Carbonator – Large

This Carbonator is ideal for small scale soda/soft drink companies. It is of simple construction, hence maintenance and cleaning are very easy. Due to its special internal construction, quality of soda is high & better gas volumes can be achieved.

Co2 gas is fed into the carbonator through a Pressure Regulating Valve from the bottom. A highly efficient three piston SS pump feeds the carbonator with water. The pump has high quality durable seals that ensures very low maintenance of the pump. Water is fed by the pump to the carbonator from the top. Inside, there is a shower & a series of SS Plates mounted one on top of the other. The water is showered inside the carbonator and trickles down the plates. This ensures thorough saturation. The whole assembly is mounted on a SS stand. The carbonator is pre-insulated to preserve water temperature. An Automatic Liquid Level Controller is also fitted to switch the motor on or off according to the level of water inside the tank.

The Pump and motor are fitted below the tank and covered on three sides to protect them from getting wet.

The size of the carbonator is 12” diameter x 5.0 ft height and output capacity is about 750 LPH. It can be altered for premix carbonation also.

Rinser with 12 Cups – for PET Bottles

This unit is meant for rinsing 12 PET bottles at a time. It can be fitted on top of a cement/plastic or SS Tank. It has 12 nozzles fitted on SS pipes and connected to a central pipe with ball valve which is connected to a water source like overhead tank or pump. All contact parts are SS 304.

12 Bottles are kept upside down in the nylon cups. When the ball valve is opened, water jets into the bottles and rinses them. The rinse water falls back into the tank below and can be drained or recycled as required. About 24 bottles can be washed in a minute depending on the speed of the operators. The unit requires very little maintenance.

The Rinser can wash any size of PET bottle from 200 ml to 2000 ml. It can also be altered to suit bottles of different mouth diameters, shapes and sizes

Rinser with 2 Nozzles – Press Type for PET Bottles

This rinser is ideal for quick high pressure jet rinsing of PET bottles with pressurized water. A ½ Hp I ph monoblock pump is fitted on the machine for this. It can be used for rinsing all Pet bottles from 200 ml to 2000 ml. It consists of a stand and tray on which the two nozzle rinser is fitted. The pump is installed below the tray. An NRV is fixed on the pipe line from pump to rinsers so that when the bottles are not rinsed, the water flows back to reservoir. So the pump can run continuously and need not be switched on and off.

The Rinser consists of two spring loaded nozzles. When two bottles are pressed upside down on the nozzles, the bottles are flushed with a jet of water. The rinse water falls back in to the tray below from where it can be drained or recycled as required.

The water collection tray, stand and rinser nozzles are all made of SS 304. About 12-14 bottles can be rinsed per minute – but this depends on the speed of the operators.

Rinser with 12 / 24 Cups with Pump & Tray for PET Bottles

- The Motorized Rinser is ideal for high-speed jet rinsing of P ET bottles.

- The pump must be used in case overhead tank is not available.

- The Rinser is mounted on a portable SS table with a water collection tray.

- A monoblock pump is provided to jet the water into the bottles.

- Water connection is made to the inlet of the pump.

- The outlet of the pump is connected to the three way ball valve of the Rinser.

- The bottles are kept upside down in the rubber cups.

- Ball valve is opened and the bottles are rinsed.

- The rinsing water falls back into the collection tray and can be reused after filtration or drained.

- Once the rinsing is over, the three way ball valve can be closed to load the next lot.

- Mean while the pump is on and the pumped water is recycled back through the third port of the ball valve.

- About 24 / 48 bottles can be washed per minute depending on the speed of the operator.

Motorised Liquid Stirrer

- The Stirrer is basically a mixer with a fan blade at the bottom.

- It is used for stirring /mixing liquids like juices, syrups, curd etc.

- It is also most useful in the food, rubber, chemical and other industries where a homogeneous mix of the liquid is critical to product quality.

- The Stirrer consists of a high-speed motor mounted on a bell housing from where four stainless steel rods extend down and support a frame of stainless steel plates with holes.

- The motor shaft is connected to the fan blade at the bottom with a central stainless steel shaft.

- The stirrer is hung inside the container holding the liquid with the help of a wire rope and winch provided. The bottom of the stirrer is kept about six inches above the bottom of the container.

- When the motor is switched on, the central shaft turns and rotates the blade.

- The blade pushes the liquid through the holes in the stainless steel frame and thus the liquid is broken up into bits and mixes well.

- The stirrer is used for 10 – 30 minutes as required.

- The size of the stirrer may vary according to the quantity of liquid to be mixed at a time.

- The stirrer has an advantage over the conventional mixers in that the liquid is mixed by breaking it up rather than making it revolve in the container.

- This Stirrer with a ½ Hp I Ph motor can mix about 100 liters of liquid at a time.

- If the liquid is too viscous or foaming type, the Stirrer can be specially made to suit the liquid quantity & application required.

Motorised Volumetric Liquid Filling Machine

The Volumetric Liquid Dosing Machine is ideal for filling non-viscous liquids in accurate preset quantities. The quantity per fill can be adjusted. It is meant for liquids without particulate matter.

The machine consists of a motor and gear box and has one or two pumps attached as required. Each pump has two hoses connected to it – one is for liquid suction and the other is for liquid delivery into the filling medium.

The suction hose can be connected or dipped into the container holding the liquid to be filled. Liquids can be filled in glass bottles, PET bottles, Tins, Cans or pouches as required. The number of bottles that can be filled depends on the volume of output per fill, density of the liquid & mouth diameter of the container being filled.

It is an easy machine to use and requires little maintenance limited to the change in washers in the pump and oil for the gear box.

The machine is available with the following options:

| Fill Range | Output / Minute | Motor HP |

|---|---|---|

| 5 ml – 50 ml | 56 BPM | ½ HP |

| 20 ml – 100 ml | 56 BPM | ½ HP |

| 50 ml – 300 ml | 28 BPM | ½ HP |

| 100 ml – 500 ml | 14 BPM | 1 HP |

The main advantages of the machine are:

- The machine is sturdily built of SS 304 and all contact parts are also SS 304.

- It can fill hot liquids (up to 80 degrees Celsius) also.

- For this the inlet and outlet hoses provided are Silicon Braided.

- Bottle Tables to hold the bottles while filling can be provided.

- Accurate fill quantities

- Fast filling

- No spillage & wastage

- Liquid fills untouched by hand.

- The pumps can be easily dismantled for cleaning after use.

Soda / Soft Drink Filler for – PET Bottles Manually Operated Single Head (Direct Filler)

- This table-mounted unit is an additional filler used for filling soda /soft drinks in PET bottles.

- This machine must be connected to a Carbonator.

- PET bottles of size 200 ml to 2000 ml can be filled.

- No mounting adjustments are required.

- The bottle is placed on the bottle holding plate and the bottom lever pressed.

- When the filling valve lever is pressed, soda starts flowing into the bottle.

- When the bottle is full, the filling lever is released. The bottom lever is also released and the bottle can be taken off.

- T o make soft drinks, the bottles are pre-filled with required amount of syrup concentrate. Then soda is filled on the machine – the soda and syrup mix inside the bottle to make soft drink.

- A ‘Snift’ Valve is fitted to release the air inside the bottles during filling.

- The machine requires very little maintenance except for washers and springs that generally wear out.

Soda / Soft Drink Filler – for PET Bottles Manually Operated Two Head ( Direct Filler )

This is an easy to use twin head soda/soft drink filler for PET bottles. It can be fitted on a wall or a stand. Holes are provided for this. The unit can be connected to a Carbonator with the help of connecting pipe provided. The machine is compact and sturdily built of SS square pipes.

Two PET Bottles are placed on the neck holding plates. Any bottle of size from 200 ml to 2000 ml can be filled. A lever provided below the heads is pressed upwards and the bottle mouths get locked into place in the filling heads. The soda inlet ball valve is opened and soda flows into the bottles. Two air release ‘Snift’ valves are provided in front of heads. Air in the bottle is released when the bottles are filling. When the bottles are full, the ball valve is closed. Now the bottles can be taken off.

About 10-12 bottles (of size 300 ml) can be filled per minute depending on the speed of the operator. To make soft drinks, the bottles are pre-filled with the required quantity of syrup flavour and then soda is filled. The soda and syrup mix inside the bottles to make soft drink.

The machine requires very little maintenance limited to change of washers and springs. It does not require any expert maintenance which can be done by the user.

Soda / Soft Drink Filler – for PET Bottles – Manually Operated Four Head (Direct Filler)

This is an easy to use four head soda/soft drink filler for PET bottles. It can be fitted on a wall or a stand. Holes are provided for this. The unit can be connected to a Carbonator with the help of connecting pipe provided. The machine is compact and sturdily built of SS square pipes.

Four PET Bottles are placed on the neck holding plates. Any bottle of size from 200 ml to 2000 ml can be filled. A lever provided below the heads is pressed upwards and the bottle mouths get locked into place in the filling heads. The soda inlet ball valve is opened and soda flows into the bottles. Four air release ‘Snift’ valves are provided in front of heads. Air in the bottle is released when the bottles are filling. When the bottles are full, the ball valve is closed. Now the bottles can be taken off.

About 20-24 bottles (of size 300 ml) can be filled per minute depending on the speed of the operator. To make soft drinks, the bottles are pre-filled with the required quantity of syrup flavor and then soda is filled. The soda and syrup mix inside the bottles to make soft drink.

The machine requires very little maintenance limited to change of washers and springs. It does not require any expert maintenance which can be done by the user.

Soda / Soft Drink Filler – for PET Bottles Manually Operated (Counter Pressure Filler)

This machine is a compact single head PET bottle Soda/Soft drink filler. It is a counter pressure filler. It can be installed on a table top or a bench. It is an easy to use machine. A production of about 3-4 bottles can be done per minute. The machine is connected to a Carbonator with the help of connecting pipe provided. Soda flows from the Carbonator to the tank of the machine where it is stored. The tank is fitted with a pressure gage to monitor the gas pressure and a safety release valve. An automatic air relief valve is provided to relieve air from the tank from time to time. A gage glass tube is provided to check the level of soda in the tank.

A special locking type clamp is fitted on the machine. The bottle is first placed by its neck on the bottle holding plate. In case of glass bottles, a bottle table is provided. Then the locking clamp lever is lifted up and locked into position. The bottle goes up in to the filling head. A small L Type Lever provided in front of the tank is turned to start the counter pressure and automatic filling. Once the filling has reached the nozzle, the L Lever is turned back into the lock position. Then the snift lever in front of the tank is pressed to release excess ressure and the bottle can be taken off for capping. It is an easy machine to use with very little maintenance and with minimum loss of carbonation during filling hence ensuring a strong soda. To make soft drinks, the bottles are pre-filled with the required syrup flavor.

(Machine can also be used for glass bottle with minor alterations)

Soda / Soft Drink Filler – Two Heads – for PET Bottles Pneumatically Operated (Counter Pressure Filler)

This is a compact machine for filling soda/soft drinks in PET bottles. It can fill two bottles at once. It is pneumatically operated and easy to use. Its hexagonal soda tank is made out of thick SS 304 sheet to withstand pressure. It has a pressure relief valve, pressure gage and an automatic air release valve to improve soda quality.

Two bottles are kept on the neck holding plates. The first pneumatic hand lever is pressed – the bottles go up and are locked on the filling valves. When the second pneumatic hand lever is pressed, the filling valves open. After counter pressure, the soda starts filling. Once the soda is filled in the bottles to the required level, the filling valve is closed. The snifting knob in the front of the tank is pressed. After snifting the bottles can be brought down and taken off for capping.

Any PET bottle of size from 200 ml to 2000 ml can be filled. The machine can fill about 4 bottles per minute of 300 ml size. For larger bottles, production will be less. But production also depends on the dexterity and speed of the operator.

The machine has very low maintenance and requires a few washer changes from time to time depending on its usage. It is user serviceable and does not require special expertise for this. It is available with four filling heads and PLC controlled also with minor changes the machine can also be used for filling glass bottles.

Soda / Soft Drink Filler – Four Heads -for PET Bottles – Pneumatically Operated (Counter Pressure Filler)

This is a compact machine for filling soda/soft drinks in PET bottles. It can fill Four bottles at once. It is pneumatically operated and easy to use. Its exagonal soda tank is made out of thick SS 304 sheet to withstand pressure. It has a pressure relief valve, pressure gage and an automatic air release valve to improve soda quality.

Four bottles are kept on the neck holding plates. The first pneumatic hand lever is pressed – the bottles go up and are locked on the filling valves. When the second pneumatic hand lever is pressed, the filling valves open. After counter pressure, the soda starts filling. Once the soda is filled in the bottles to the required level, the filling valve is closed. The snifting knob in the front of the tank is pressed. After snifting the bottles can be brought down and taken off for capping. PET Bottle capping machines are also available with us.

Any PET bottle of size from 200 ml to 2000 ml can be filled. The machine can fill about 8-12 bottles per minute of 300 ml size. For larger bottles, production will be less. But production also depends on the dexterity and speed of the operator.

The machine has very low maintenance and requires a few washer changes from time to time depending on its usage. It is user serviceable and does not require special expertise for this. It is available with two / eight filling heads and PLC controlled also. With minor changes the machine can also be used for filling glass bottles.

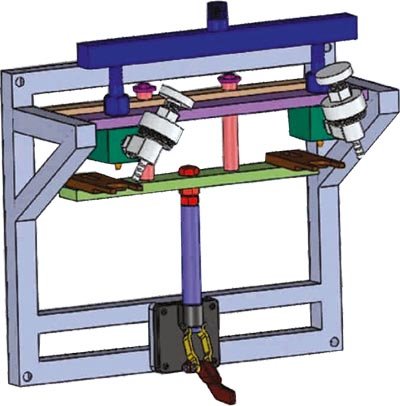

Soda / Soft Drink Filler – Four Heads for Pet Bottles – Pneumatically Operated PLC Controlled (Counter Pressure Filler)

This machine is ideal for small scale units for making soda/soft drinks in PET Bottles. The machine is pneumatically operated by a PLC (Computer controlled). It can fill all sizes of bottles from 200 ml to 2000 ml. It can be quickly programmed according to bottle size. A control panel is provided for this. The machine must be connected to a suitable Carbonator.

The machine consists of a tank in which soda from the Carbonator is stored. It has a safety release valve, a pressure gage to monitor tank pressure, an automatic air relief valve to release air from the tank from time to time and a gage glass tube to check the level of liquid in it. A compressed air line from air compressor must be connected to it. For this an FRL is provided.

Four bottles are kept on the neck holding plates. When a switch is pressed on the control panel, the bottles automatically go up. The counter pressure, filling, snifting and bottles release are all taken care of by the PLC. The operator takes off the four filled bottles and the cycle is continued. The bottles can now be capped.

To make Soft drinks, the syrup concentrate is previously filled into the bottle. The bottle is then kept on the machine and soda filled. The soda mixes with the syrup inside the bottles and the soft drink is ready. For small scale units which have limited production, this method of soft drink production is ideal because any flavor can be filled at any time without having to clean the system every time a different flavor is filled.

The Counter pressure method of filling ensures that during the filling there is no loss of carbonation. The machine is very easy to use and requires very less maintenance limited to change of washers, springs & oil change in FRL from time to time.

Output of the machine is about 8 – 10 bottles per minute (of 300 ml size). But this may be less for larger size of bottles. Production also depends on the operator speed. All contact parts are SS 304.

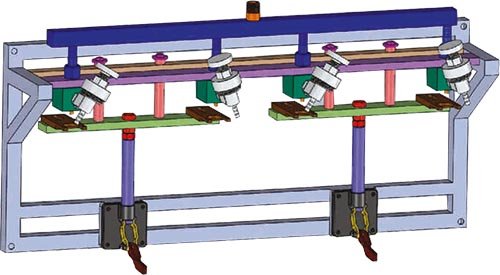

Soda / Soft Drink Filler – Eight Head – for PET Bottles Pneumatically Operated PLC Controlled (Counter Pressure Filler)

This machine is ideal for small scale units for making soda/soft drinks in PET Bottles. The machine is pneumatically operated by a PLC (Computer controlled). It can fill all sizes of bottles from 200 ml to 2000 ml. It can be quickly programmed according to bottle size. A control panel is provided for this. The machine must be connected to a suitable Carbonator.

The machine consists of a tank in which soda from the Carbonator is stored. It has a safety release valve, a pressure gage to monitor tank pressure, an automatic air relief valve to release air from the tank from time to time and a gage glass tube to check the level of liquid in it. A compressed air linem from air compressor must be connected to it. For this an FRL is provided.

The machine has eight filling heads – four on either side. So two persons are required to operate it. Each side has a control panel so both the sides can be operated independently. Each operator keeps four bottles on the neck holding plates. When a switch is pressed on the control panel, the bottles automatically go up. The counter pressure, filling, snifting and bottles release are all taken care of by the PLC. The operator takes off the four filled bottles and the cycle is continued. The bottles can now be capped.

To make Soft drinks, the syrup concentrate is previously filled into the bottles. The bottles are then kept on the machine and soda filled. The soda mixes with the syrup inside the bottles and the soft drink is ready machine. For small scale units which have limited production, this method of soft drink production is ideal because any flavor can be filled at any time without having to clean the system every time a different flavor is filled.

The Counter pressure method of filling ensures that during the filling there is no loss of carbonation. The machine is very easy to use and requires very less maintenance limited to change of washers, springs & oil change in FRL from time to time.

Output of the machine is about 16 – 20 bottles per minute (of 300 ml size). But this may be less for larger size of bottles. Production also depends on the operator speed. All contact parts are SS 304.

Soda / Soft Drink Filler – Semi Automatic Rotary for PET Bottles (Counter Pressure Filler)

This machine is ideal for small scale units for filling soda/soft drinks. It is a counter pressure filler for best quality strong soda/soft drinks. It can fill any size of PET bottle from 200 ml to 1.5 liters. The machine is available with 6 / 9 / 12 filling heads. For 300 ml bottles, the output will be as follows:

- 6 head filler – 24 BPM

- 9 head filler – 30 BPM

- 12 head filler – 36 BPM

It is provided with a control panel. The speed of rotation can be adjusted. The machine is easy to use. The operator keeps one bottle at a time on the neck holders as the tank rotates.

Filling takes place automatically and the bottles are taken off after filling. It requires a premix carbonator which is also supplied by us. A conveyor can also be supplied with the machine for taking off the filled bottles and for capping, shrink wrapping and batch coding on it.

The machine is powered by a 1 HP III ph motor and suitable gear box and has the following features -A ‘No Bottle No Fill’ lever ensures that the valve opens only when a bottle is placed and avoids unnecessary soda loss.

The main features of the machine are:

- The filling valve is closed automatically when the filling is over

- A snift valve is provided to release excess gas before the bottles are taken off to avoid foaming

- An automatic air release valve is provided to vent air from the filling tank

- A pressure gage is provided to monitor tank pressure at all times

- A pressure safety release valve is provided on the tank

- The machine is made fully of SS 304 grade material

PET Bottle Capping Machine – Motorised

- This Capping Machine is used for capping PET bottles.

- Any PET bottle can be capped. However the capping die may vary according to the cap diameter.

- The Capper is powered by a 1/4 hP I PH motor with an attached gearbox.

- The capping die is fitted on the output shaft of the gearbox. The die rotates at an approximate speed of 100 RPM.

- After the PET bottle is filled, the cap is placed on it and the bottle with cap is pressed into the rotating Die.

- The rotating Die then automatically h olds the cap and tightens the cap on the bottle. This whole operation takes about 4-5 seconds depending upon the dexterity of the operator.

- A torque setting is provided to ensure the correct tightness of the cap.The amount of tightness required can be adjusted with the help of spring-loaded ball provided.

- The advantage of the machine is that all the bottles are evenly tightened and operator fatigue is low.

- An optional stand is available to fix the machine on a wall or table.

- About 10 bottles can be capped per minute.

PET Bottle Capping Machine – Pneumatic

This is an easy to use machine for capping plastic bottles – fast. It is very handy and portable and can cap about 10-12 bottles per minute depending on the user’s speed. It must be connected to an air compressor. An FRL must be fitted in the pipe from air compressor to the machine.

It has a torque setting which ensures that the cap is tightened exactly as much as required. The cap is placed on the bottle and the Pneumatic Capper is ressed on the cap. It is tightened and stops once the set torque is reached.

It’s unique features are:

- Being pneumatically operated , it requires very

- little maintenance except for oil in the FRL.

- Easy to use and requires very little skill.

- It is light weight and portable.

- Uses minimum quantity of air only when it is actually capping.

- No electrical connection and therefore free from short circuits

and carbon brush problems.

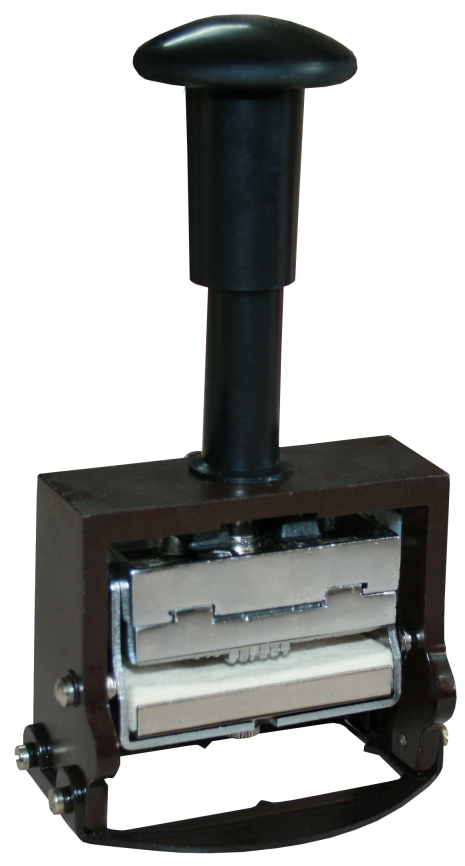

Hand Operated Batch Coding Machine – Manual

The Hand Operated Batch Coder is a handy machine for printing batch number, MRP, date of mfg etc as required. It can print three or four lines. The unit is available for printing on various surfaces like plastic, metal, wood, paper, ceramic and glass – on bottles, lids, caps, jars, labels, laminated cartons, tins, cups etc. It can print on flat and curved surfaces. For each application a model is available.

A complete set of alphabets, numbers and symbols are provided. These are available in sizes from 2 mm to 10 mm depending on whether they are metallic or rubber. A bottle of special fast drying ink is supplied with the coder.

The machine is also supplied with a wooden base for printing on soda/soft drink glass bottles. It is also available pneumatically operated. The machine can be fitted on automatic Form Fill Seal Packing machines for printing on pouches as they are formed, filled and packed.

Automatic Inkjet Coding Machine with Conveyor

This is an “ANSAR” make INKJET Coding Machine model PRO S for printing on porous & non-porous surfaces like PET, metal, plastic, wood & paper. It can be used for printing on bottles, caps, labels, boxes, bags etc. It has the following unique features –

- Cartridge is suitable for 2.5 lakhs to 2.75 lakhs prints of three lines each which makes it extremely cost effective.

- Display of the printer of 3.5 inch LCD screen with LED back light

- User interface has a simple and easy to use operating system

- Input device is a pocket sized IR remote key pad

- Available languages are Chinese, English, German, Spanish etc,

- Size of the of the printer is 119 mm x 78.8 mm x 76.0 mm

- Weight is 550 gms

- Mounting orientation can be horizontal or vertical

- Operating temperature is 5 degrees Celsius to 50 degrees Celsius

- Data interface is RS485, USB port

- Can be integrated with FFS machines, band sealers, taping machines and other packing machines for printing on labels, bags and pouches.

- The most significant advantage of the U2-ProS and TIJ printers in general is that they are virtually zero maintenance devices. Once a cartridge is exhausted, it merely has to be replaced with a new piece. There is no ink reservoir, make-up or complicated parts that need regular replacement like most large character or CIJ printers.

Shrink Wrap Tunnel – All Purpose Economy – Floor Model

- Shrink-wrapping is one of the most popular and convenient forms of packaging.

- Shrink-wrap packaging involves the use of thermoplastic or thermo setting films that shrink when heat is applied to them.

- This machine is suitable for Shrink wrapping of all types of items like individual or sets of bottles, labels on bottles, containers, packets etc.,

- It is a simple machine, easy to operate and requires no formal training.

- Once the machine is switched on and temperature is set, the shrink-wrapping can commence.

- The film is first wrapped/sealed around the product. It is then placed on the inlet of the machine. It goes in on a conveyor and comes out at the other end shrink-wrapped.

- The heat tunnel size, price and other factors are governed by the product size.

The main advantages of Shrink Wrapping are:

- Economical

- Protects the product from dust, moisture and humidity.

- It is a hygienic form of packaging for foodstuffs.

- Can be used for making multi packs and adds value to the product.

- Gives the product a good look and helps reduce pilferage

- Can be used to package any product of any size or shape.

- Shrink-wrapping material can be pre-printed.

The machines have the following unique features:

- Digital variable speed conveyor.

- Fan with special impeller for even heat circulation in the tunnel.

- Various models to suite your requirements.

- Separate control panel box for protection.

- Digital temperature controller.

- Silicon / Teflon covered roller.

Shrink Wrap Tunnel with Plastic Film Wrapper for Packing PET Bottles

This is a Shrink Film Wrapper and Heat Shrinking Machine for packing PET Bottles. Shrink Wrapping is now a days considered a cheaper and better option in place of cardboard boxes.

The machine is in two parts – the Shrink Film Wrapper and the Heat Shrink Tunnel. The Wrapper has been provided with a set of guides to be adjusted according to the number and size of bottles to be packed. The Shrink Tunnel is provided with a metallic mesh conveyor to withstand temperature, suitable heaters, temperature sensor and controller to maintain the required temperature and a set of fans to circulate the heat inside the tunnel. The machine is controlled by a central control panel where the temperature inside the tunnel, the speed of the conveyor, the fans and other functions can be easily controlled.

The PET bottles are kept on a table on the Wrapper. The operator then presses a switch and the machine automatically wraps the shrink film over them. The bottles are now moved forwards by the machine. Meanwhile the operator can keep the next set of bottles. The first set of wrapped bottles now move into the shrink tunnel. The shrink wrapped bottles come out of the other end of the tunnel where another fan cools down the plastic film. The packed bottles are now taken off. The process continues as each set of bottles are placed one after the other.

The wrapping of the film takes place pneumatically and so an air compressor is required. It has height adjustable washers on each of its legs so the Wrapper and the Tunnel can be aligned on the same level. It has a set of holders on the top and at the bottom to hold the shrink film roll which have to be fixed.

The width of the film rolls will vary according to the number and size of bottles to be packed.

The machine has a sturdy powder coated MS body built for a long life. Both the Wrapper and Shrink Tunnel have wheels below so they can be moved easily. With minor adjustments that can be done quickly, PET bottles of any size from 200 ml to 2000 ml can be packed. Note that the machine can be used for other items like cardboard boxes, glass bottles, regular and irregular shaped objects etc can also be packed.

Labeling Machine – for PET / Glass Bottles

This is a compact table top self adhesive labeling machine for round PET and Glass Bottles. It can also be used for labeling round Cans / Tins. Ideal for small scale industries for quick & neat labeling. It is a simple machine to use.

The labels in roll form are loaded into the machine in the slot provided for this. One bottle is kept on the bottle table horizontally. When the handle is turned once, one bottle gets labeled. The machine can be used for bottles with different diameters and lengths.

The machine is made of powder coated mild steel and is sturdily built. It requires minimal maintenance. About 10-12 labels can be applied per minute depending on the operator’s speed.

Gas Volume Tester – for Glass & PET Bottles

- This is an easy to use unit for determining the ‘Gas Volumes’ of a soda/soft drink.

- ‘Gas volume’ is a unit determined by the pressure inside a bottle and the temperature of the liquid.

- The Gas Volume Tester is basically a quality-checking unit.

- One or two bottles are taken out from the production line at regular intervals.

- The Tester is first clamped on the bottle to be checked. Then the bottle is punctured with the spindle by rotating the knob and the pressure noted on the pressure gauge.

- The Tester is then removed, bottle opened and the temperature of liquid checked.

- Both values are noted and the ‘gas volumes’ found by referring chart provided.

- Soda and various soft drinks have varying ‘gas volumes’ and the values have to be adhered to get the best quality.

- The Tester is available for both glass & PET bottles.

- It is made of SS 304.

Semi Automatic PET Bottle Capper Pneumatically Operated

This a timer based Pneumatic PET Bottle Capper. The capper is basically a “Chicago Pneumatic” torque tightening tool. It is fitted on a stand with a timer. The worker keeps a filled bottle with the cap, on a neck holding plate. The plate goes up and down at the time set by the operator. The machine tightens the cap at the torque set on the machine and bottle is brought down. The capped bottle can be taken off and the next bottle is kept. Since the capper is fitted on the machine it need not be manually held — thus reducing operator fatigue.

It’s unique features are:

- Being pneumatically operated, it requires very little maintenance.

- Easy to use and requires very little skill.

- It is light weight and portable.

- Uses minimum quantity of air only when it is actually capping.

- No electrical connection and therefore free from short circuits and carbon brush problems.

- The time between each capping can be set as per the convenience of the operator.

- About 12-15 bottles can be capped depending on the speed of the operator.

- A 1 HP air compressor is required for this machine.

Syrup / Liquid Filling Machine

This is a simple liquid filling machine. All liquids which have density almost similar to water can be filled. Any quantity from 5 ml to 1 liter can be filled. The machine is provided with two timers on its front panel — one timer sets the fill quantity per bottle and the other timer is to set the cycle time —that is the time between each fill.

The machine is made out of SS 304 and is a table top model. It has two hoses — one for the liquid suction which can be dipped into the container holding the liquid and the other can be held in hand for filling in each bottle. The fill and cycle times can be easily set.

The machine is robustly built and is portable. It requires very little maintenance except the cleaning by pumping water through the hoses for a few minutes after the filling is over. The machine is warranted for a period of one year.

Table Top Soda/Soft Drink Maker

The Table Top Soda/Soft Drink Maker is a unique compact machine ideal for way side shops, stalls, cottage level industries etc for making carbonated drink and serving on the spot. It is easy to use and does not require any training except for a few basic concepts. The machine is available for both glass and PET bottles.

A bottle is filled with water & premixed flavours. The bottle is then fitted on the machine. A lever is pressed for releasing the CO’ into the bottle. The liquid is carbonated and the bottle can be taken off. A fast workercan do about 3-4 bottles per minute.

The main features of the machine are:

- CO’ is stored in the MS tank of the machine which is tested for high pressure.

- The CO’ inlet valve on the machine is of good quality.

- It is easy to use.

- PET bottles of all sizes from 300 ml to 2000 ml can be used without any adjustment or setting.

- The machine requires very low maintenance except for change of washers once in a few days depending on the daily volume of usage.